BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

Integrated printing has higher structural strength and more accurate dimensions than CNC disassembly process

Integrated printing has higher structural strength and more accurate dimensions than CNC disassembly process

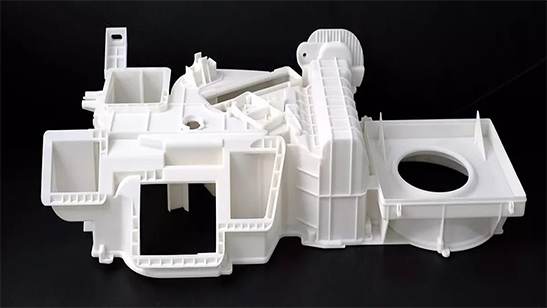

3D printing automotive air conditioning -HVAC large complex parts are formed in one body, with better precision and strength

HVAC is the abbreviation of English Heating Ventilating Air Conditioning, that is, heating, ventilation and air conditioning, which is installed under the vehicle instrument with heating, ventilation and air conditioning functions, including blower assembly, heater core, evaporator core, mixed damper, mode damper and other major components.

SLS nylon 3D printing is made in one piece, which has higher structural strength and more accurate size than CNC disassembly process.

Automotive air conditioning HVAC plastic shell and air duct, is a relatively large 3d printing plastic parts in the automotive body interior, it plays the role of carrying or assembling other parts, for its strength, impact resistance, high temperature resistance and corrosion requirements are more strict, is a more important part of HVAC. With the continuous development of the automotive industry, the design and manufacture of HVAC assemblies need to meet the following technical requirements:

Continuous temperature resistance: -40℃~+120℃; The tensile strength of the shell material is greater than 55MPa, and the Young's modulus is greater than 3500MPa. Need to be formed as a whole, small shrinkage deformation; High dimensional accuracy is required, some dimensional accuracy is ±0.1mm, and the total length error is less than 0.3mm; The material has flame retardant requirements, flame retardant grade UL94-V0. The total length of HVAC shell is more than 950mm, and has a very complex structure. SLS nylon 3D printing is made in one piece, which has higher structural strength, more accurate size and less deformation than CNC disassembly process. Compared with the overall molding process of the silicone mold, the products made by SLS 3D printing are easier to control whether the wall thickness size or the structural size, and its structural strength is high and can be repeatedly disassembled and assembled, which can be directly used for the sample car and the preliminary design verification and data collection, saving the time of mold making and welding fixture production, and speeding up the early research and development process of the car.

Compared with the traditional process, processing an automotive air conditioning HVAC shell, 1 SLS 3D printer only takes 2 days, CNC requires 2 equipment processing for 3 days, and silicone mold process takes 5 days, bringing higher efficiency to industrial customers!

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.