We provide on-demand CNC turning services for rapid prototypes and production parts .

Application of CNC turning service

Lori is an experienced precision CNC turning service manufacturer in China. We are committed to providing the best OEM CNC turning lathe service for high quality and low cost CNC turning parts or high precision CNC Turning machining parts. We have state-of-the-art lathes and use CNC lathes with live tooling. So CNC turning is commonly used for functional prototypes and end-use parts, parts with cylindrical characteristics, parts with axial and planes, radial holes, grooves and slots.

Therefore, Lori as a CNC turning company, we can providing services suitable for mass production of high precision CNC turning parts. Our CNC turning services are mainly used in consumer electronics, medical instruments, optical equipment, automotive, lighting industry and other industries. CNC turning is the most basic, the most extensive and the most important technology in the machinery manufacturing industry.

| Size Limit | Metric | Imperial | |

Maximum Dimensions | Diameter | 550 mm | 21.65 inches |

| Length | 990mm | 39 inches | |

Minimum Dimensions | Diameter | 4.07 mm | 0.16 inchs |

| Length | 1.27 mm | 0.05 inchs | |

| Tolerances | / | +/- 0.13mm | +/- 0.005 inchs |

| Material | Available Types & Grades |

| Aluminum | Aluminum 2024, Aluminum 5052, Aluminum 5083,Aluminum 6063/6061, Aluminum 6082, Aluminum 7050/7075, and more details. |

| Brass/Bronze | Brass 260, Brass C360, C932 M07 Bearing Bronze, and more details. |

| Copper | Copper C110, Copper 101, and more details. |

Stainless Steel | Stainless Steel 17-4, Stainless Steel 18-8,Stainless Steel 303/304/304L,Stainless Steel 316/316L,Stainless Steel 416/420, and more details. |

| Plastics | POM,ABS,Nylon,PEEK,PMMA,PTFE,PVC ,Polystyrene,Polyethylene,Polycarbonate,PET,HDPE, PP , PC and more details. |

| Titanium | Titanium Grade 2, Titanium Grade 5, and more details. |

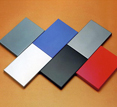

| Finishing | Description | Materials | ||

| Anodizing | Ordinary anodizing, Hard anodizing, Conductive anodizing | Aluminum | |

| Electroplating | Chrome plated, Galvanized, black zinc plating, Gold-plated, Silver plated, black nickel plating,Tin plating, Nickel plating, black chromium plating, Decorative chrome plating | Aluminum, steel, stainless steel, brass, bronze, copper | |

| Powder Coating | Powder coating is a coating applied in the form of free flowing dry powder. Unlike traditional liquid coatings, which are delivered by evaporating solvents, powder coatings are usually electrostatic sprayed and then cured under heat or ultraviolet light | Aluminum, Stainless Steel, Steel, ABS | |

| Bead Blasting | The parts produced by bead blastion have a smooth surface with a matte texture. Primarily for visual applications and subsequently for other surface treatments. | ABS, Aluminum, Brass, Stainless Steel, Steel | |

| Polishing | Polishing refers to the process of using mechanical, chemical, or electrochemical effects to reduce the surface roughness of a part, in order to obtain a bright and flat surface. It is the use of polishing tools and abrasive particles or other polishing media to modify the surface of parts. | Aluminum, Stainless Steel, Steel, Brass, | |

| Sand blast | Sand blasting process is the use of compressed air as the power to form a high-speed jet beam, the jet material and other high-speed jet to the surface of the workpiece to be treated, so that the parts surface to obtain a certain degree of cleanliness and different roughness, so that the workpiece surface mechanical properties are improved. | Aluminum, Stainless Steel, Steel, ABS | |

What is CNC Turning

CNC turning is a typical reduction manufacturing process that uses cutting tools to remove part of the material from the outside. As the workpiece rotates (continuously rotates), excess pieces are chipped away until the desired shape, diameter, and dimensions of the final product are reached. CNC turning is suitable for cutting metals, wood, plastics and other polymers. In addition, because the process uses computer-generated programs and codes, its products tend to have high dimensional accuracy.

CNC Turning involves rotating and turning the work piece, usually the material being processed is cylindrical or circular. However, CNC turning can work with different shapes of materials when using compatible adapters. It is important to note that there are different tools on the turret of a CNC lathe or CNC turning center, and the more cutters that can be accommodated, the more complex the machine is and the better suited it is for complex designs.

Types of CNC Turning Perations

Straight line CNC turning: Linear CNC turning involves using a cutting tool to reduce thediameter of the workpiece evenly. The technology is designed to process the material to a specified thickness. It can quickly remove part of the material, thereby preventing changes in the diameter of the product. It is sometimes called a rough car and requires additional machining to obtain dimensional accuracy.

Knurling: This operation involves the introduction of jagged, angled, or crossed cutting patterns on the workpiece surface. The craft usually introduces a firm grip, as the pattern increases friction. It is also suitable for making bolts and nuts for threaded holes. It is worth noting that this operation may require a specially designed knurled tool.

Segmentation: Segmentation is a processing technique that uses a single point cutting tool to create a deep groove in the material to remove its internal components. As the name suggests, it results in producing parts or cutting off parts of the original.

Tapered turning: Tapered turning involves gradually reducing the diameter of the material from one end to the other. The angular motion between the material and the cutting tool causes the workpiece diameter to transition and decrease. As with most turning operations, the final product is cylindrical.

Thread machining: Threading is another CNC turning process that involves the cutting tool moving along the side of the material to cut the thread onto the external parts of the work piece. A thread is a spiral groove of a specific length and spacing.

Slotting: This CNC turning operation creates a narrow cut a groove in the workpiece. It involves the action of a sharp tool head on a material to cut at the same width as thecutting tool. With the help of a variety of cutting tools, wider diameter grooves can be machined.

Let's Start Your CNC Turning Projects. Please Get an Online Quote

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.