BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

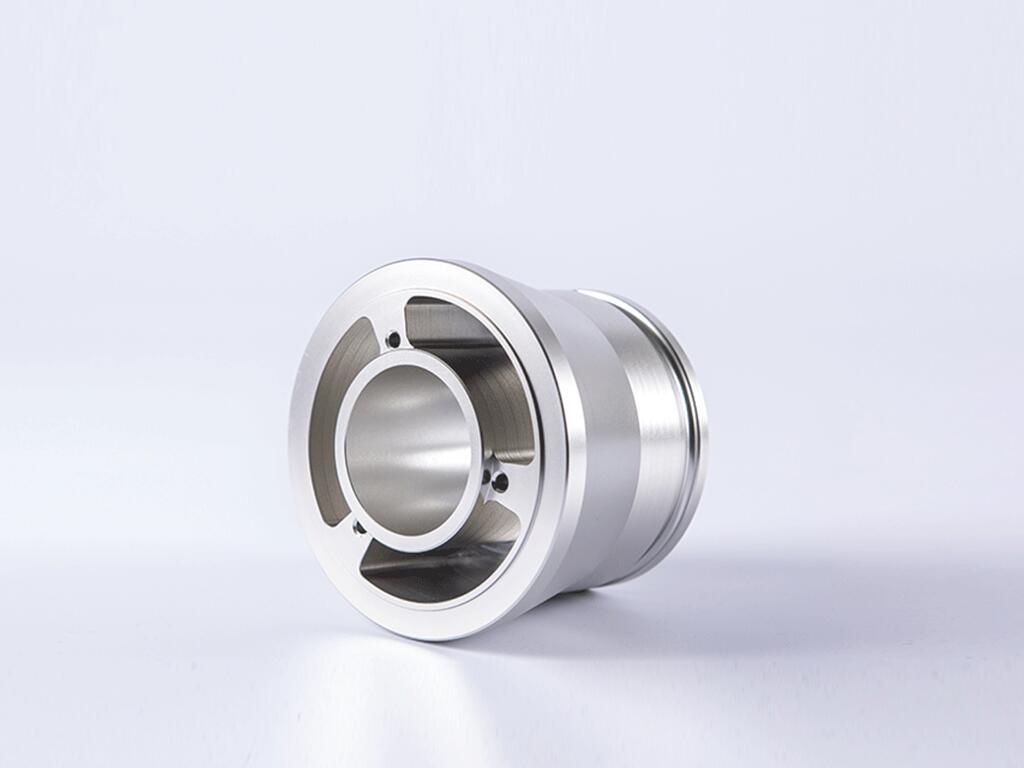

1. Hip replacement and knee implants

Like any other machined medical hardware, body implants, such as knee implants and hip replacements, require a high level of precision and accuracy. A slight error in the manufacturing process can have a significant impact on a patient's life.

Swiss CNC machines help to precisely manufacture patient-specific parts while achieving tolerances as small as 4μm. After receiving a request from an orthopaedic surgeon, the CNC machining center creates a CAD model and recreates the body parts through reverse engineering and CNC technology.

The medical industry requires that these implants be made of biocompatible materials, such as PEEK and titanium. These materials are challenging to process - they generate too much heat during processing, and coolants are often prohibited due to concerns about contamination. CNC machines are helping to solve this challenge because of their compatibility with multiple materials.

2. Production of surgical tools

Complex surgical procedures require highly accurate, specialized tools. These instruments range from simple scalpels and scissors to complex robotic arms for minimally invasive surgery. These tools must be manufactured with high precision. cnc machining plays a vital role in the production of surgical tools required for various medical procedures.

CNC machines can achieve complex geometry and tight tolerances, making them ideal for producing complex surgical tool designs. For example, robot-assisted surgical instruments can be machined using numerical control technology to ensure the highest accuracy, enabling surgeons to perform complex surgeries with greater precision and fewer complications.

3. Electronic medical equipment

Many medical devices, such as MRI scanners, heart rate monitors and X-ray machines, are equipped with thousands of CNC-machined electronic components. Examples include switches, buttons, and levers, as well as electronic housings and housings.

Unlike implants and surgical tools, these medical devices do not need to be biocompatible because they do not come into direct contact with the patient's internal systems. However, the manufacturing of these parts is still largely overseen and controlled by multiple regulatory agencies.

Failure to comply with the standards set by these regulators can result in heavy fines (and sometimes even imprisonment) for machine shops. There have also been cases of medical professionals involved having their medical licenses revoked. Therefore, you must choose your medical device manufacturer wisely.

4. Custom prosthetics

Personalization is becoming increasingly important in healthcare, and nowhere is this more evident than in the field of prosthetics. Patients need prosthetic devices that perfectly fit their bodies, and traditional mass production techniques often fail to meet their needs.

cnc machining is transforming the field of prosthetics, making it possible to produce custom devices based on the unique physiological characteristics of each patient. Using 3D scanning and CAD modeling, CNC machines can create prosthetics with complex details and high-precision dimensions, ensuring optimal function and comfort for patients.

Using numerical control technology, prosthetic limbs can be produced with high precision, ensuring comfort and full functionality.

5. Small orthopedic hardware

Orthopaedic devices such as plates, screws and rods are widely used in the medical field to repair or replace damaged bones and joints. Given the critical role these devices play in patient recovery, they must be manufactured with the highest precision and quality.

cnc machining plays a vital role in the production of these orthopedic instruments. CNC technology is capable of machining complex geometric shapes with high precision, making it ideal for the production of these devices. In addition, cnc machining can handle a variety of biocompatible materials, including titanium and stainless steel, which are commonly used in orthopedic devices.

6. Prototype of medical equipment

Before mass production of any medical device, it is critical to create a prototype for testing and validation. CNC machining provides a fast and cost-effective solution for the production of medical device prototypes. With the ability to quickly generate multiple iterations of a design, engineers can test and improve equipment to ensure its safety, effectiveness, and compliance with regulatory requirements.

This ability is critical in the fast-paced world of medical device development, where the ability to quickly bring new products to market can be a significant competitive advantage. CNC machining can also produce small batch prototypes, allowing manufacturers to minimize waste and save on material costs during development.

7. Dental tools and implants

cnc machining is essential for providing high quality dental care by creating custom dental tools and implants. Dentists around the world rely on advanced CNC technology for precision treatment. This technology is ideal for making durable instruments such as drills, tooth cleaners, probes, and tweezers that are essential for a variety of surgeries.

The production of these devices requires exceptional durability to withstand sterilization while ensuring patient safety. CNC manufacturing provides repeatability and strict quality control, guaranteeing that every tool meets strict standards.

Dental implants provide a long-term solution for missing teeth and require precise customization using CNC manufacturing technology. These implants are created based on digital scans, ensuring an accurate and personalized fit for each patient. cnc machining has revolutionized the production of dental restorations and improved treatment outcomes.

Through the efficient use of materials such as titanium and zirconia, numerical control technology enables precise modifications with superior efficiency and effectiveness.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.