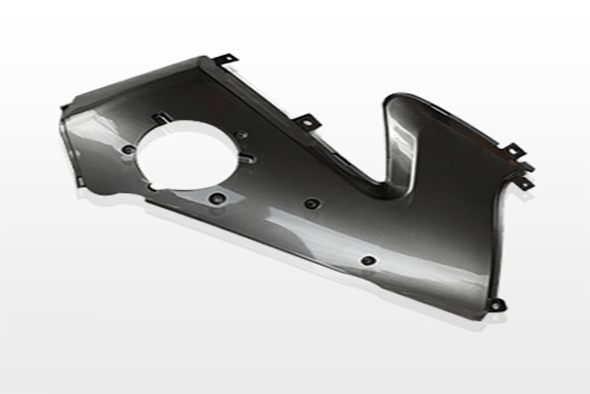

The coloring and surface texture decoration of Lori can be completed when the plastic is formed, but in order to increase the life of the Injection molding products and improve their beauty, the surface is generally processed twice and a variety of decorative treatments are carried out. Injection molding methods for surface finishes are: