BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

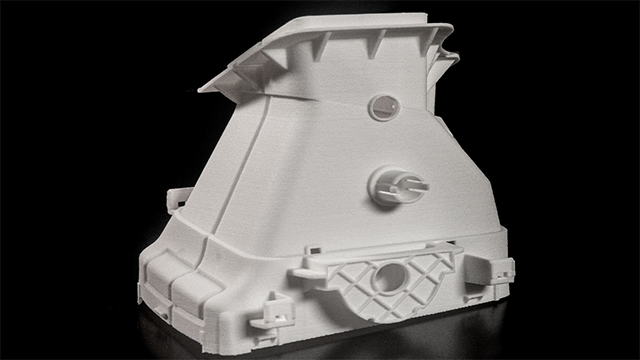

Resource efficiency of SLS 3D printing processes. The manufacturing breakthrough allows printing with up to 100% reused powder, which is an important step for the company to help customers make sustainable choices.

Lori’a sls 3d printing technologis are committed to reducing the "orange peel" effect that can be observed when the powder is reused. Due to the cooling of the layer, this effect results in uneven surfaces and reduces part strength. To overcome this shortcoming, Lori uses two lasers, one for sintering new layers, while the other maintains a certain temperature to keep the previous layer at the correct temperature.

Lori’a sls 3d printing technologis is committed to reducing the "orange peel" effect that can be observed when the powder is reused. Due to the cooling of the layer, this effect results in uneven surfaces and reduces part strength. To overcome this shortcoming, Lori uses two lasers, one for sintering new layers, while the other maintains a certain temperature to keep the previous layer at the correct temperature.

Up to half of the powder used in the selective laser sintering process becomes scrap, and the recycling of this used powder is often limited, making it unsuitable for reuse in other 3D printed parts

According to us, the resulting parts have similar mechanical and visual properties to other powders used in selective laser sintering, which means that users can choose not only its environmental indicators, but also its technical specifications.

Typically, the SLS printing process of validating a single part can require up to a thousand test samples that rely on trial and error, which is often time-consuming and expensive. Lori claims that its process regulator predicts suboptimal prints by combining advanced automation, artificial intelligence (AI), and intelligent simulation, significantly reducing the number of physical test prints required to find the best print setup for a part.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.