BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

| Place of Origin: | Shenzhen, China (Mainland) | Type | CNC stainless steel parts |

| Technology: | CNC Machining Milling | Maximum Size | 1500+ mm |

| Material: | Stainless steel | Shape: | Customized shape |

| Packing: | Standard export packing | Brand Name: | LORI |

| Application: | Automation robot | Certificate: | ISO 9001:2015,ISO 14001:2015 |

| Model Number | LR-T-0011 | Tolerance: | +/-0.0 mm |

| Finish: | Electroplating | Size: | Custom size, mm |

| Process: | CNC milling | Processing capacity | 10000 pieces per day |

| Drawings | Auto CAD, JPEG,PDF,STP, IGS, and most other file formats are accepted | Production Flexibility | Prototype, small, and high volumes |

| Processing equipment | 4-axis CNC machining center, 5-axis CNC machining center, 3-axis CNC machining center, High-speed engraving and milling machine, Drilling and tapping machine, CNC lathe, industrial 3D printer, Injection molding machine, | ||

| Testing equipment | Coordinate measuring instrument, 2D measuring instrument, Inner micrometer, Outer micrometer, Electronic height meter, Hardness meter, Thread stop gauge, External thread ring gauge, Electronic caliper, | ||

| Quality Control | 1. Material quality inspection 2. Precision quality inspection 3. Appearance quality inspection 4. Function quality inspection 5. Structural inspection 6. Surface treatment inspection 7. Packaging inspection | ||

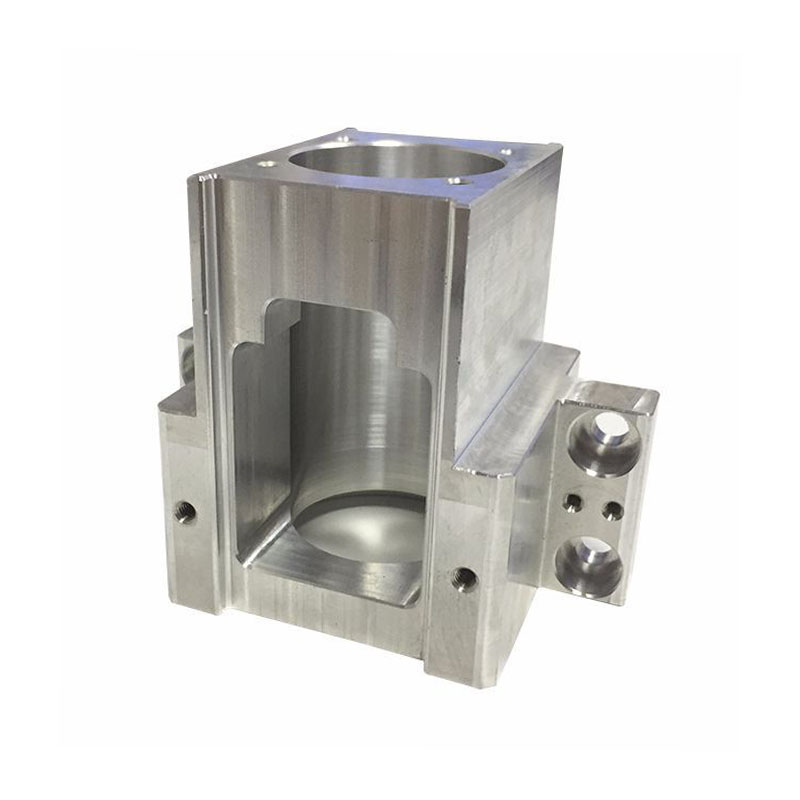

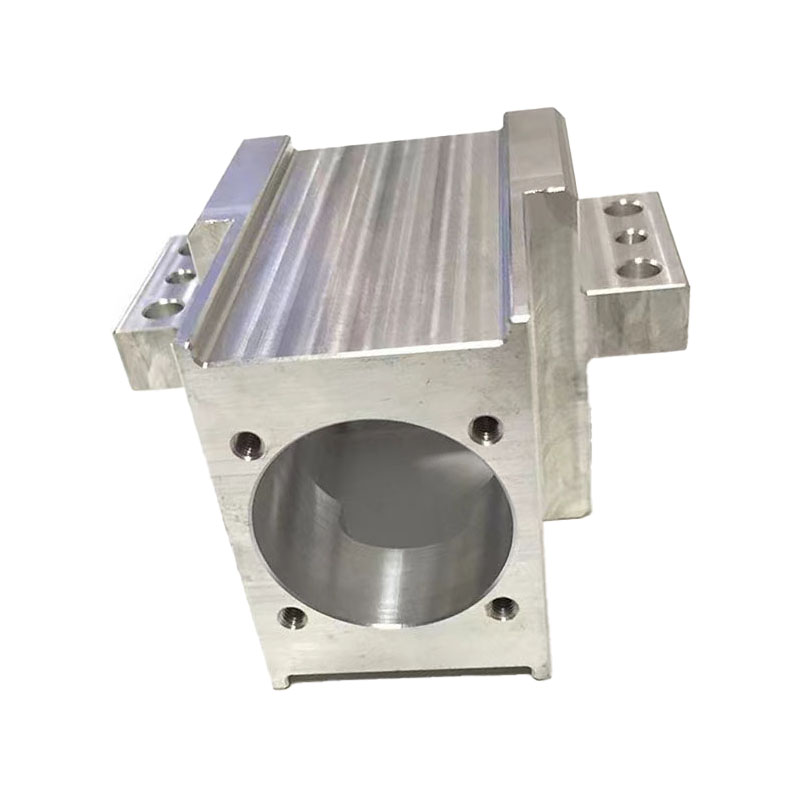

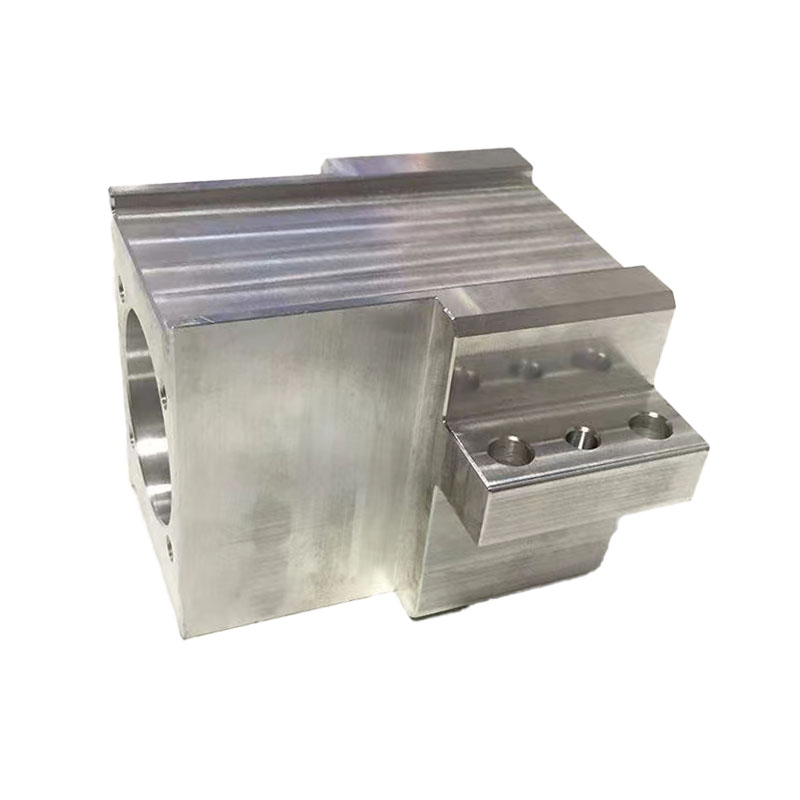

CNC Stainless Steel Precision 5-Axis Milling Machining Parts For Automation Robot

Lori has been specialized in CNC stainless steel precision milling machining for 10 years,and is the world's leading CNC stainless steel machining milling parts provider. Our company has invested in several CNC machining centers and CNC turning-milling compound machining centers. We can process many different types of precision CNC aluminum machining turning parts with high difficulty and complex shapes. Our best tolerance is ±0.001mm. In addition to CNC turning and milling, we can offer different types of CNC machining services or solutions, and Lori is constantly innovating in technology. If you would like to know more about CNC machining aluminum turning, please contact us or get a instant quote.

CNC stainless steel milling machining is a precision CNC machining technology that brings exceptional quality and precision to your products. By combining the two processes of turning and milling together, we can achieve a more efficient and accurate machining process. Whether you need to manufacture parts with complex shapes or improve production efficiency, Lori CNC stainless steel milling machining can meet your needs.

Materials for CNC Milling Parts :

Plastics: ABS, PC, PE, POM, PP, acrylic, nylon, bakelite, silicone rubber,

Metal: Aluminum alloy, zinc alloy, magnesium alloy, titanium alloy, stainless steel, sheet metal, steel, copper, iron

Surface Finishing for CNC Milling Parts:

Anodizing, electroplating, sandblasting, painting, oil spraying, plastic spraying, grinding, polishing, screen printing, wire drawing, blackening,

laser marking, radium carving, surface etching, adhesive coating, vacuum film, dental guard, copper nut,

High precision

Processing complex shapes

High production efficiency

Excellent surface finish

Lori is a professional CNC stainless steel precision milling machining parts manufacturer with advanced machines including CMC machining center and turning machining centers from the general 3-axis to 5-axis. Our experienced operators are well versed in CAD(Computer Aided Design) and CAM(Computer Aided Manufacturing) programs and always find the best way to produce the highest quality NC mished parts and components for our customers. So we can can cost-effective customized CNC milling parts, including 3-axis CNC milling parts, 4-axis milling parts and 5-axis milling parts for high-speed CNC manufacturing, rapid prototyping. Our precision CNC machining stainless steel milling parts are involved in the field of automation design, automobile parts machining, medical equipment, defense industry,machinery milling, lighting parts machining, etc. Send your inquiry or drawing fast to get an online CNC turning quote.

Lori is a CNC turning machining parts manufacturer in China offering services suitable for mass production and rapid prototyping of high precision CNC turning machining parts, such as components for medical devices, mobile phone, optical equipment, automobile, lighting industry, office equipment, etc. We can know that CNC turning machining has become the most basic, the most extensive and the most important technology in the machinery manufacturing industry, which directly affects production efficiency, cost, energy consumption, and environmental protection.

When you are looking for custom CNC lathe turning and milling composite turning machining for custom aluminum alloy parts , Lori can provide you with high precision custom CNC turning and milling parts, accepting small batch orders and allowing for a variety of different material options. Lori is an expert in turning machining with a comprehensive range of turning machining capabilities, from prototypes to complex designs with tight tolerances, which sets us apart and we have the ability and experience to work with you to design and manufacture the most complex and advanced custom cnc turning machining parts.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.