BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

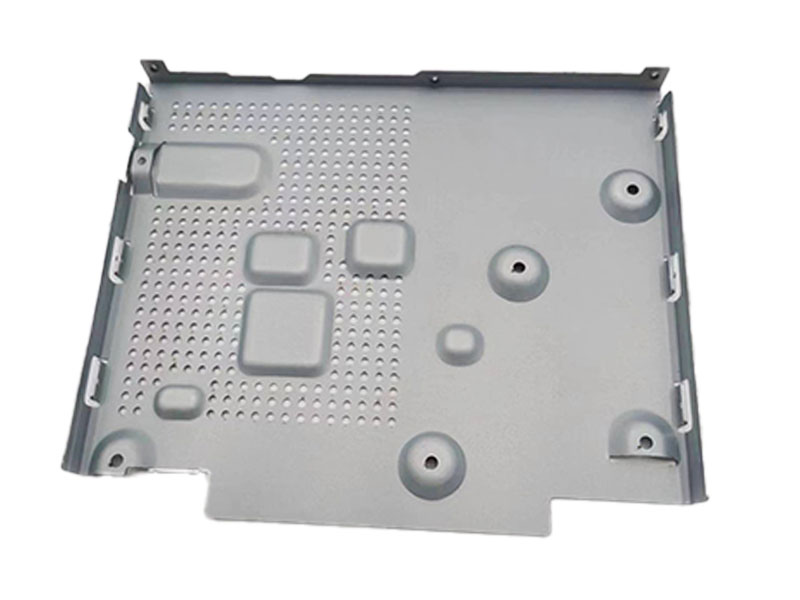

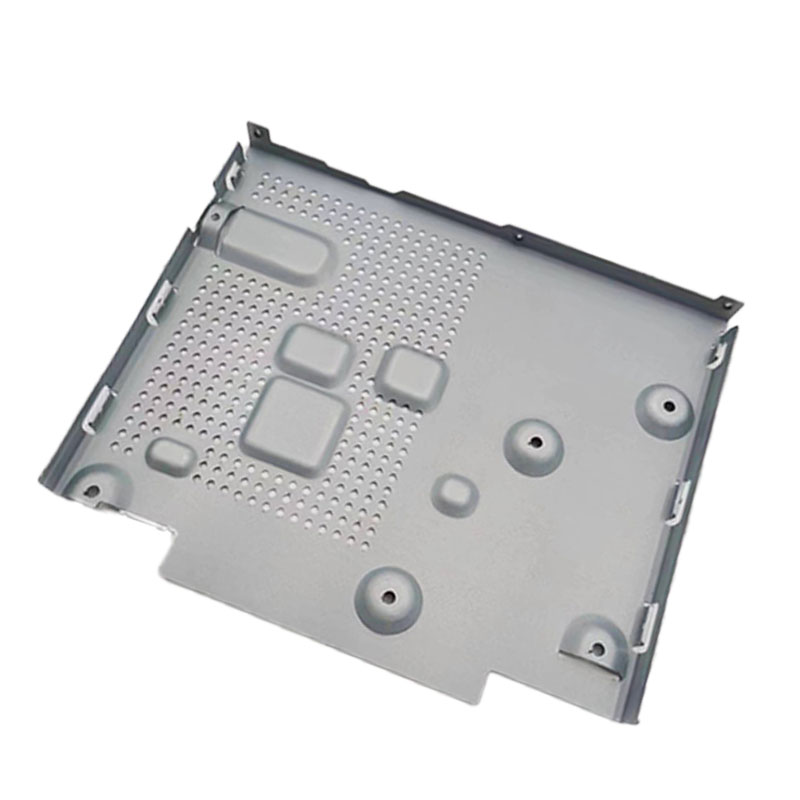

| Place of Origin: | Shenzhen, China (Mainland) | Type | Sheet metal chassis |

| Technology: | Sheet Metal Laser cutting&Bending | Grade | All grades are available |

| Material: | Electrolytic plate | Shape: | Customized shape |

| Packing: | PE Foam+Carton+Wooden Box | Brand Name: | LORI |

| Application: | Medical equipment, automation equipment | Certificate: | ISO 9001:2008,ISO 14001:2004 |

| Model Number: | LR-T-134 | Tolerance: | +/-0.01 mm |

| Finish: | Laser drop | Size: | 3000*1500(mm)or Custom size |

| Process: | Flanging, cutting, filleting, unfolding, stamping, forming, bending, embedding flanging, punching, ribbing | Quality control: | 100% full inspection |

| Drawings | Auto CAD, JPEG,PDF,STP, IGS, and most other file formats are accepted | Production Flexibility | Prototype, small, and high volumes |

Electrolytic Plate Laser Cutting Precision Sheet Metal Design Pedestal Components for Medical Equipment

The sheet metal component is made of electrolytic plate. And the sheet metal processing include flanging, punching, cutting, filleting, unfolding, stamping, forming, bending, embedding flanging, ribbing. Lori is a sheet metal fabrication factory, focuses on structural components, appearance components, sheet metal samples and batch customization processing sheet metal components, if you need sheet metal pedestal components, contact us, we can produce for you.

Lori focuses on high-precision and difficult precision sheet metal processing, and is good at making all kinds of shaped convex hull and special complex shape sheet metal components and structural components. Our products are widely used in many fields and sell well all over the world, which have been recognized and praised by many customers. Whether you need to manufacture components with complex shapes or improve production efficiency, Lori sheet metal machining can meet your needs.

| Aluminum | Copper | Metals | Mild steel & Bronze |

| Aluminum 6061 | Copper 101/Copper C110 | Stainless steel 301/304 | Steel 1018 (Low Carbon) |

| Aluminum 5052 | Copper 260 (Brass) | Stainless steel 316/316L | Bronze 220/510 |

Our sheet metal components materials include electrolytic plate, galvanized plate, cold rolled plate, aluminum, steel, stainless steel (201, 304 or 316), brass, copper and tinplate.

Sheet metal design options are flexible enough to meet customers' needs for certain functions.

It is possible to go from a single prototype to volume production

A wide range of surface treatment options for sheet metal components, including powder coating, spray painting, galvanizing, electroplating.

A wide selection of materials, and the choice of sheet metal materials provides a lot of room for different solutions.

Lori is one of sheet metal components manufacturers, we can provide you custom sheet metal components, sheet metal prototype components, sheet metal enclosures. We have the ability to produce fully functional sheet metal components for you in just 3 working days. We can produce partial or complete components by mechanized welding. The principle of sheet metal is to process sheet metal using different stages and processes (cutting, folding, stamping etc.) to give it the desired shape. The metal components obtained can be of varying thickness, large size and complex geometry. In order to produce your quality sheet metal components, we have a complete range of equipment: punching machine, CNC brake machine, laser cutting machine, wire cutting machine, etc.

Our custom sheet metal components have a wide range of applications, applied for industries like medical and pharmaceutical, automobile, military, hunting, plumbing, financial instruments, printing copiers, 5G communication chassis, smart home appliances, automated robots and more, sheet metal stamping components are often applied in electronic hardware, precision brass CNC turning components can also be used in engineering, home appliances, plumbing, and steam work.

◪ In order to ensure the best service to the customer , we have formulated this after-sales service system, the company solemnly to the users of after-sales service work to do the following commitment:

◪ 1.Provide online technical support for customers, and provide consulting services on related issues

◪ 2.From the date of spontaneous delivery, if there is any quality problem or quality objection to our company's customized products, please contact with us in time. After checking and coordinating, we can return and replace the products in time.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.