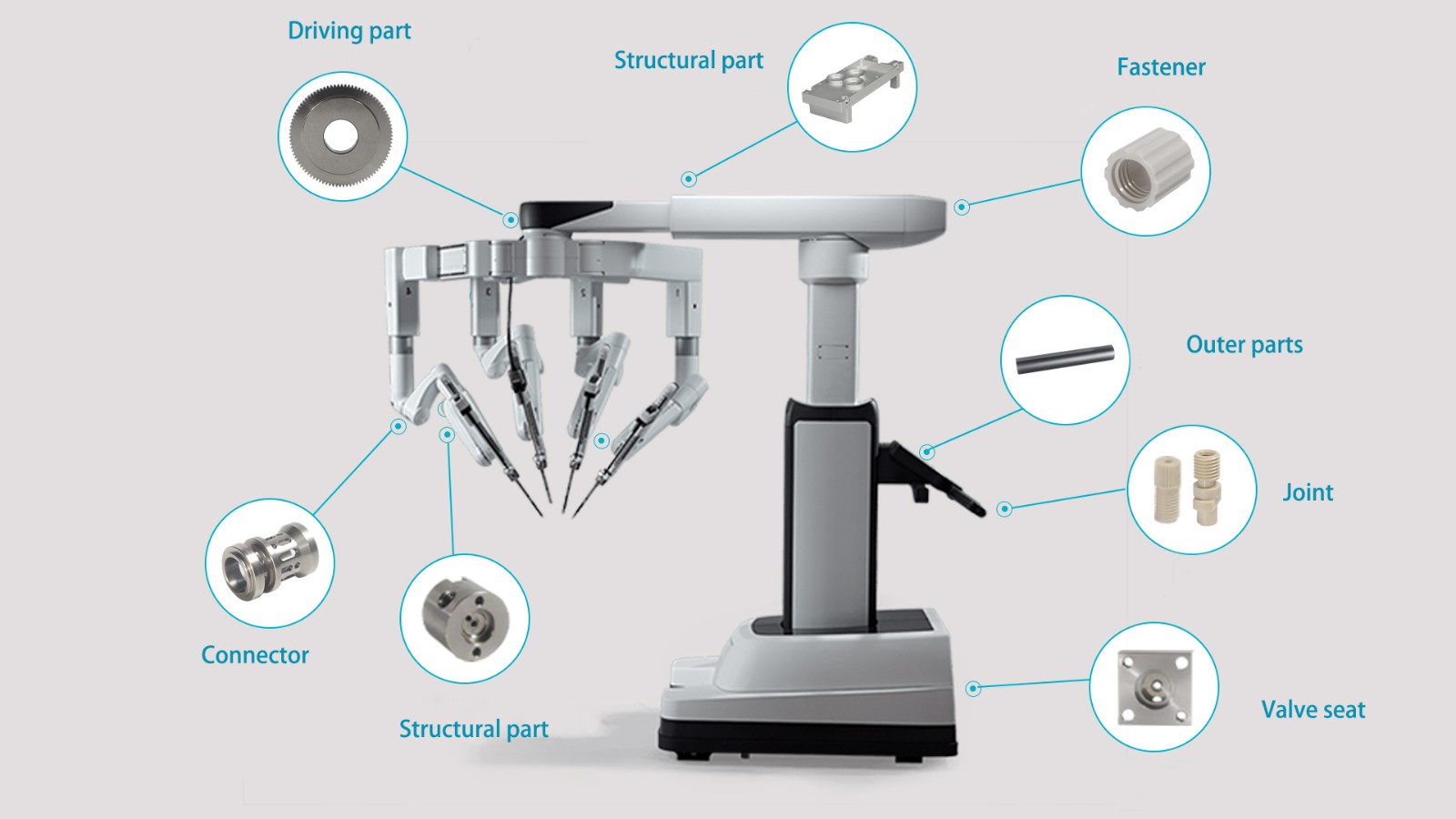

Spinal surgery robot: Currently, the main clinical operation is pedicle fixation, and the robot arm can complete the drilling operation of the implant channel independently or guide the doctor.

Orthopaedic trauma surgery robot: automatic surgery planning technology based on geometric constraints Optical tracking navigation system: real-time 3D navigation, dynamic tracking feedback of the robot high-precision control technology.