BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

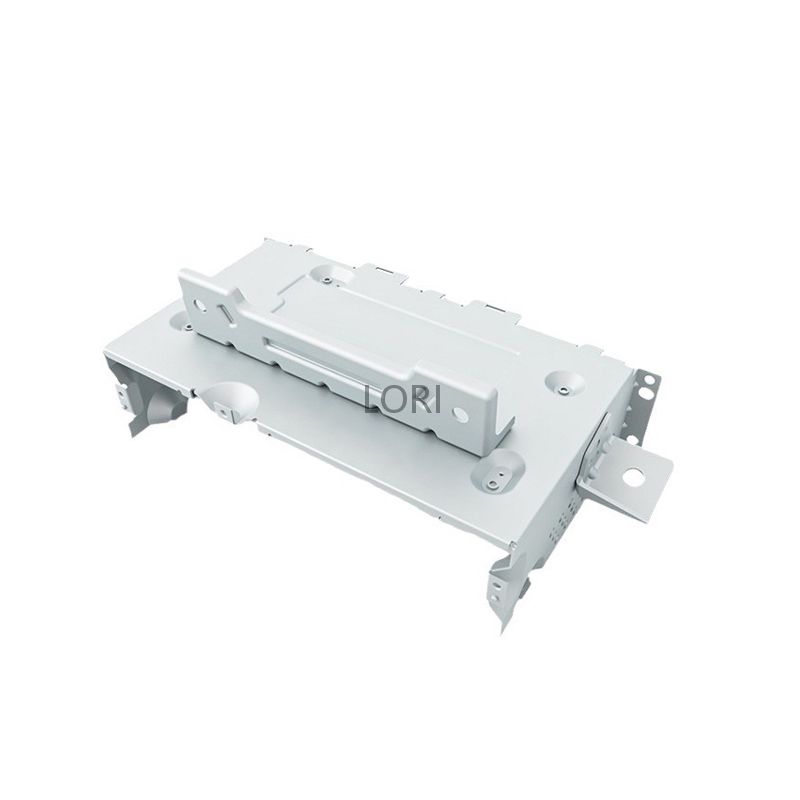

1. Introduction to Precision Sheet Metal Fabrication

Precision sheet metal fabrication includes traditional methods and processes such as cutting, stamping, and bending, as well as the principles and operational methods of various cold stamping molds, their structures, and process parameters, along with new stamping technologies.

2. Requirements for Precision Sheet Metal Fabrication

At the initial stage of sheet metal fabrication, understanding customer needs is crucial. Therefore, once an order is received, our professional team immediately engages in close communication with the customer to deeply understand the product's appearance design, forming requirements, and functional characteristics. Through detailed drawing planning and annotation, we ensure that every detail is accurately captured and perfectly realized in the subsequent processing stages.

3. Steps in Precision Sheet Metal Fabrication

The typical process flow for precision sheet metal fabrication is: Sheet Metal Design Planning → Laser Cutting or (CNC Punching) → Bending → Welding and Forming → Electrostatic Powder Coating or (Liquid Painting) → Screen Printing → Packaging and Shipping

4. Materials for Precision Sheet Metal Fabrication

Common materials used in precision sheet metal fabrication include:

-Cold Rolled Steel (SPCC): Mainly used for electroplated and baked paint parts. It is cost-effective, easy to form, and the material thickness is ≤ 3.2 mm.

-Hot Rolled Steel (SHCC): Used for electroplated and painted parts where the thickness is ≥ 3.0 mm. It is cost-effective but difficult to form, primarily used for flat components.

-Galvanized Steel (SECC, SGCC): SECC refers to electrolytic galvanized steel, divided into N and P materials. N material is primarily untreated and is more expensive, while P material is used for painted parts.

-Copper:Mainly used for conductive applications, surface treatments include nickel plating, chrome plating, or no treatment. It is high in cost.

-Aluminum Sheet: Commonly used with surface treatments like chromate conversion coating (JII-A), anodizing (conductive anodizing, chemical anodizing), silver plating, and nickel plating. It is high in cost.

-Aluminum Profiles: Complex cross-sectional structures, widely used in various enclosures. Surface treatments are similar to those for aluminum sheets.

Different materials are selected based on the product's functions, typically considering the product's application and cost.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.