BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

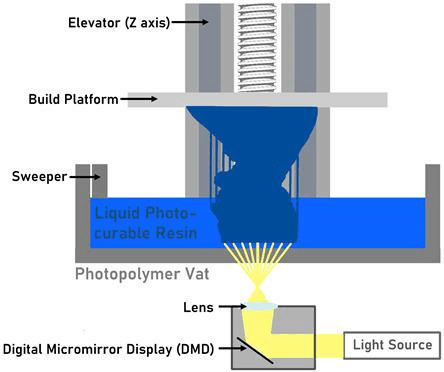

DLP (Digital Light Processing) light curing 3D printing technology is a method of 3D printing using the principle of digital light processing. The basic principle: The model is first cut horizontally into layers with 3D printing software, and then the shape of the first layer of resin model is projected, and then the light curing molding is done. The first layer of molding enlarges the object slightly and projects the shape of the next layer of model onto the resin, in turn repeating and printing the model in layers.

The basic principle of DLP light curing 3D printer

1. Projection system

DLP 3D printers use a digital projection system, which contains a DLP projector. This projector uses a microlens chip (DMD chip), which has thousands of tiny lenses on its surface, each of which can be flipped independently. These lenses can be electronically controlled so that they reflect or do not reflect light.

2, photosensitive resin

DLP light curing 3D printing uses a special photosensitive resin, which is a material that hardens when exposed to light. The formulation of photosensitive resins is often carefully designed to ensure that they have the desired physical and mechanical properties after curing.

3. Layering

The printing process starts at the bottom of the 3D model. First, a layer of photosensitive resin is evenly coated on the work platform.

4. Lighting

The projection system projects a layer of the 3D model onto the working platform. The microlens on the DMD chip adjusts the light projection so that only part of the light-cured resin layer is illuminated. In this way, specific areas in the resin harden to form a single layer.

5, the platform is reduced

Once one layer of photosensitive resin is hardened, the work platform is moved down a fixed distance to prepare for the next layer of photocuring.

6. Repeat

Repeat the above steps, and each layer of resin will be gradually stacked on top of each other until the entire object is printed.

In general, DLP light curing 3D printers utilize digital light processing technology to build objects by shining light sensitive resins on each layer. The advantages of this method include faster printing speed and higher resolution. However, selecting the right photosensitive resin and optimizing the printing parameters are key to ensuring the final print quality.

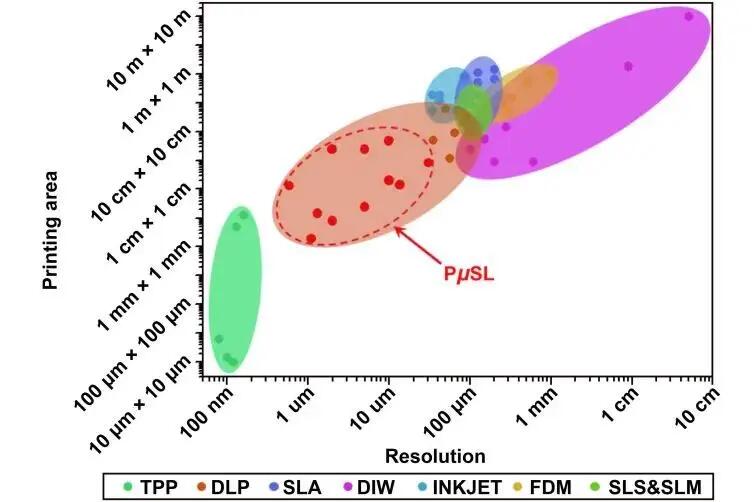

Compared with the common LCD/SLA 3d printing technology, DLP 3D printing technology has faster molding speed and higher printing accuracy, although DLP 3D printing technology has made rapid development in recent years, it still faces problems such as massive picture data transmission and storage, multi-material voxel printing accurate control, high-precision ceramic printing and other problems, which need to be solved urgently.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.