BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

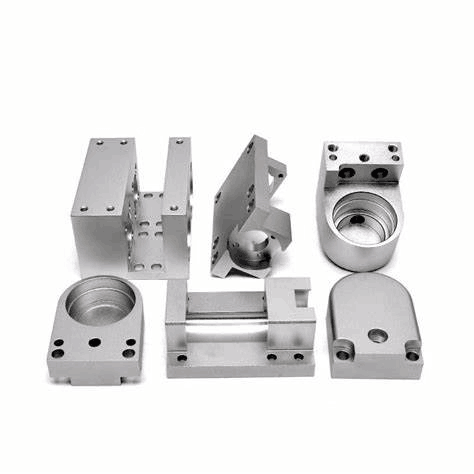

Aluminum

When it comes to CNC machining, aluminum is a standout material because of its good mechanical properties. It is lightweight but rugged, making it ideal for a variety of applications in different industries. Here are some key facts about aluminum CNC materials:

Properties of aluminum

●Lightweight: Aluminum's low density makes it an ideal material for applications that require lightweight components.

●Strong: Despite its lightweight nature, aluminum is a strong material that can withstand high stresses and strains.

●Versatile: Aluminum can be easily processed into complex shapes and complex designs.

●Corrosion resistance: Aluminum has good corrosion resistance and is suitable for use in outdoor or Marine environments.

●High thermal conductivity: Aluminum's thermal conductivity allows it to be used in heat sinks and other thermal management applications.

Application of aluminum alloy

●Aerospace industry: Aluminium in the aerospace industry is commonly used to make aircraft parts.

●Automotive industry:Aluminum is used in engine parts, wheels and other components in the automotive industry.

●Consumer goods: Aluminum is used in the production of laptop cases, mobile phone frames and bicycle frames.

●Medical industry: Aluminum is used for surgical instruments and equipment in the medical industry.

Advantages of aluminum

●Easy to process: Aluminum is easy to process, which means it can be used to create complex shapes and complex designs.

●High strength-to-weight ratio: Aluminum's strength-to-weight ratio makes it an excellent choice for lightweight applications.

●Non-toxic: Aluminum is non-toxic and safe for medical applications.

Disadvantages of aluminum

●Lower hardness levels than some metals: Aluminum has lower hardness levels than some metals, which means it may not be suitable for high wear applications.

●More expensive than other CNC materials: Aluminum alloys can be more expensive than other CNC machining materials, such as steel or brass.

Stainless steel

Stainless steel is one of the most common CNC materials. It is known for its durability, strength and corrosion resistance. It is made by adding at least 10.5% chromium to steel to form a thin protective layer on the surface of the material to prevent rust and corrosion. Here are some important facts about stainless steel in CNC machining:

Characteristics of stainless steel

●Corrosion resistance: Stainless steel has strong corrosion resistance and is very suitable for use in harsh environments.

●High strength: Stainless steel is a strong CNC material that can withstand high stresses and strains.

●Temperature resistance: Stainless steel maintains its strength and shape even at high temperatures, suitable for applications involving heat.

Application of stainless steel

●Medical industry: Stainless steel has the advantages of wear resistance, corrosion resistance, easy disinfection, etc., and is a commonly used material for surgical instruments and medical equipment.

●Aerospace industry: Stainless steel is often used in aircraft components because of its high temperature resistance and high strength.

●Automotive industry: Stainless steel is used in automotive exhaust systems, engines and other CNC machining parts that require strength and corrosion resistance.

●Consumer goods: Stainless steel is used in the production of kitchen utensils, tableware and jewelry because of its corrosion resistance and beautiful appearance.

Advantages of stainless steel

●Corrosion resistance: The main advantage of stainless steel is corrosion resistance, suitable for use in harsh environments.

●High strength: Stainless steel is a strong material that can withstand high stress and strain.

●Aesthetic: Stainless steel has an attractive appearance, making it widely popular in consumer goods.

Disadvantages of stainless steel

●High cost: Stainless steel can be more expensive than other common materials, such as aluminum or plastic.

●Difficult to process: Stainless steel is a difficult material to process, which makes machining it more challenging than other CNC machining materials.

Orichalcum

Brass is a unique material with excellent machinability and aesthetics, making it a popular choice in CNC machining. With its durability and corrosion resistance, it is a reliable choice for a variety of industrial applications such as shipbuilding and construction. Here are some key facts about brass in CNC machining:

Characteristics of brass

●Excellent machinability: Brass is known for its excellent machinability, which makes it easy to work and allows for the creation of complex designs.

●Corrosion resistance: Brass has good corrosion resistance, can withstand contact with water, suitable for use in the Marine environment.

●Durable: Brass is a highly durable material that can withstand high-stress environments and harsh conditions.

●Aesthetic: Brass has a unique color and aesthetics, making it a popular choice for decorative parts.

Application of brass

●Ornaments: Brass is often used to make ornaments, such as sculptures, vases and jewelry.

●Musical Instruments: Brass is often used to make trumpet, trombone and other Musical Instruments.

●Pipe fittings: Brass has become a common material for pipe fittings such as taps and valves because of its corrosion resistance and durability.

●Electrical components: Brass is often used in connectors, switches and other electronic components.

Advantages of brass

●Aesthetic: Brass has a unique color and aesthetics, making it a popular choice for decorative parts.

●Excellent machinability: Brass is known for its excellent machinability, which makes it easy to work and allows for the creation of complex designs.

●Corrosion resistance: Brass has good corrosion resistance, can withstand contact with water, suitable for use in the Marine environment.

Disadvantages of brass

●Limited strength: Brass is less strong than other metals such as steel, which means it may not be suitable for high-stress applications.

●High cost: Brass can be more expensive than some materials, such as aluminum or plastic, which can make it less cost-effective for some applications.

TO BE CONTINUED...

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.