BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

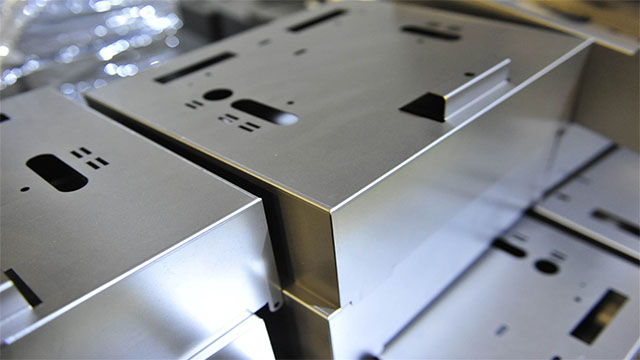

1. High precision

Sheet metal processing using numerical control processing, can be accurate to 0.1MM, to meet the requirements of high precision. Therefore, sheet metal processing has been widely used in parts manufacturing areas that require high precision and high quality, such as automobiles, electronics, communications and other fields.

2. Low cost

Compared with other processing methods, sheet metal processing equipment is low in price, easy to operate, and only a small number of workers are required to complete the production. Therefore, sheet metal processing costs are relatively low, which can bring good economic benefits to manufacturers.

3. High production efficiency

Due to the use of CNC machine tools in the sheet metal processing process, automated production can be achieved, so the production efficiency is high, and labor and time costs can be saved. Therefore, in the field of mass production, sheet metal processing has obvious advantages.

4. Low environmental pollution

Compared with other processing areas, sheet metal processing has little environmental pollution. Sheet metal processing does not need to use chemicals, paint and other harmful substances, so it will not pollute the environment.

5. A wide range of processing materials

Sheet metal processing can be processed for different metal materials, including steel, aluminum, stainless steel, copper, etc., and different materials can be selected for processing according to user needs.

In conclusion, sheet metal processing has the advantages of high precision, low cost, high production efficiency and low environmental pollution. With the development of the manufacturing industry, the application range of sheet metal processing is more and more extensive, and the future will also have broader development prospects. Please contact us to custom sheet metal processing parts!

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.