BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

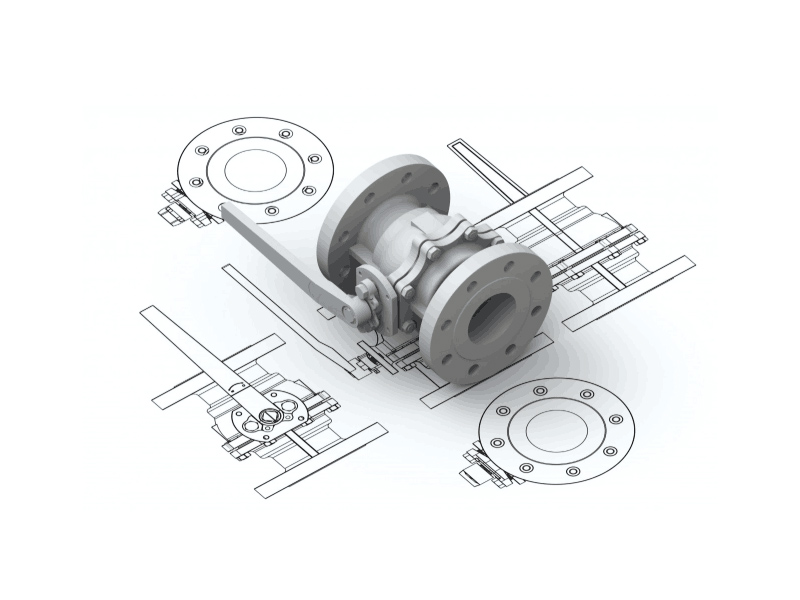

The prototyping process generally consists of the following four steps:

1. Design Stage:

- In this stage, the initial design of the product is created using hand drawings, CAD design software, or other tools. The focus is on determining the product's size, shape, and functional requirements.

2. Manufacturing Stage:

- Here, the design drawings or 3D models are used to produce the prototype. This stage involves selecting the appropriate materials and manufacturing methods, such as CNC machining, 3D printing, or laser cutting, to ensure the prototype meets design specifications.

3. Testing Stage:

- The manufactured prototype undergoes inspection and testing to verify that it meets the design and functional requirements. This stage focuses on evaluating various parameters, such as strength, wear resistance, and service life.

4. Correction and Improvement Stage:

- After identifying issues during testing, the prototype is corrected and improved. This stage involves analyzing test results and making necessary adjustments to enhance the prototype's quality and performance.

In summary, the prototyping process includes design, manufacturing, testing, and improvement stages. Each stage is crucial and must be meticulously executed to achieve optimal results.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.