BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

What is the difference between CNC milling machines and machining centers? In fact, this problem is not only very confusing for laymen, but also unclear for many people in the industry. Simply put, the machining center is an upgraded version of the CNC milling machine, if the CNC milling machine is compared to the steel saint, then the processing center is the gold Saint.

In fact, these two kinds of processing equipment mainly have the following three differences:

First, the biggest difference is whether there is a knife library

Ordinary CNC milling machines also have CNC operating systems (such as Mitsubishi, New generation, Fanuc, Siemens, etc.), but also have three feed shafts and a rotating spindle, their processing mode geometry is exactly the same, but also basically can achieve the same processing capacity.

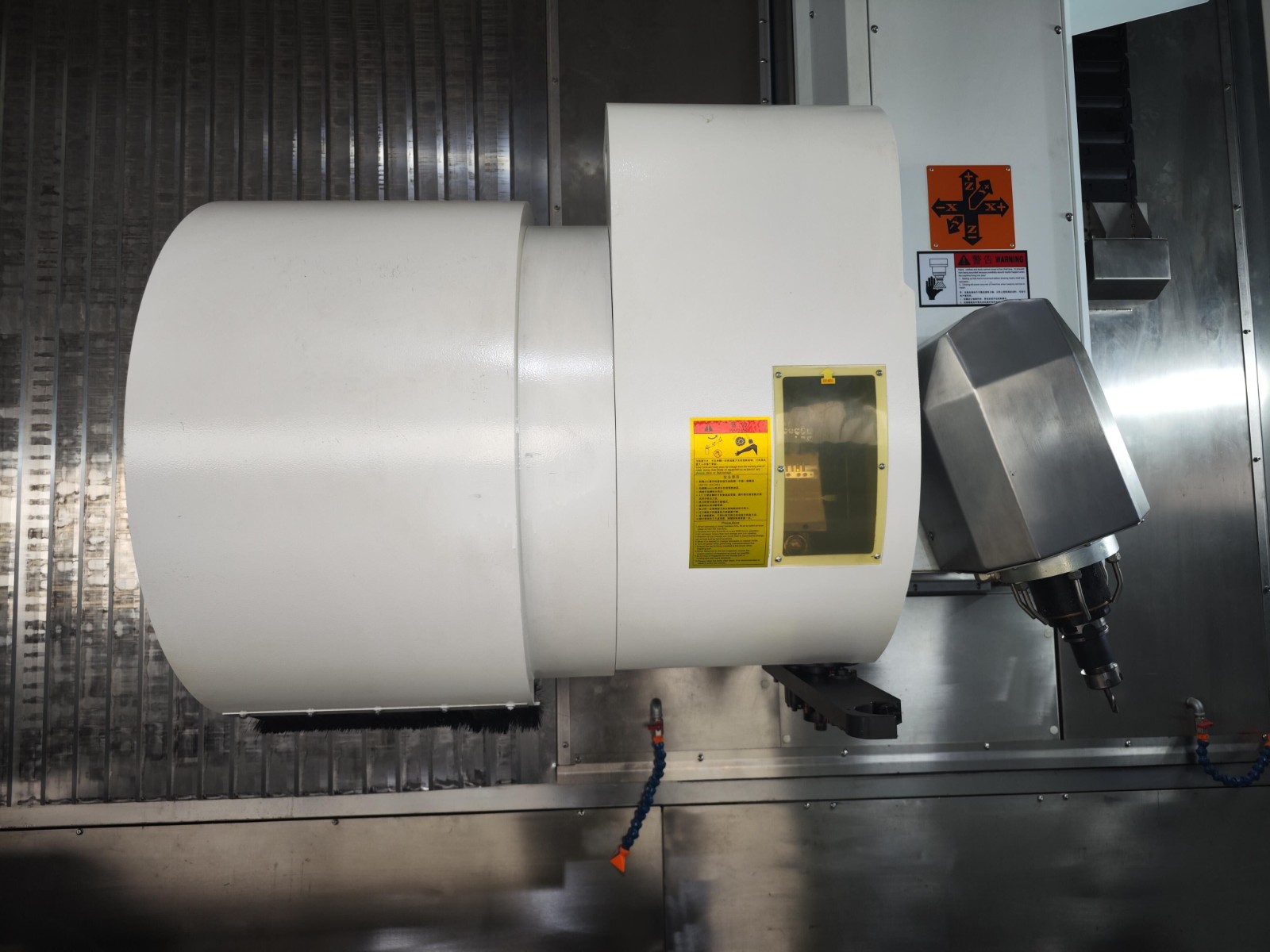

And their biggest difference is to see whether the equipment with a tool library, the machining center is actually a CNC milling machine with a tool library, the machining center can achieve a clamping and complete the work of multiple processing processes, such as milling, drilling, tapping, etc., because it can realize the automatic change of the tool, and in the continuous processing process of multiple processes, The operator does not need manual intervention, as long as the program is prepared, the tool and the corresponding parameters can be configured. Numerical control milling machine is not, numerical control milling machine can also achieve a clamping process of multiple processes, the difference is that in the process of conversion, must manually change the tool, so the processing process is discontinuous, is a number of degrees of intermittent execution, such processing whether in processing quality, or processing efficiency, are slightly inferior to the processing center.

So in the future, when you see a device, you can directly determine whether it is a CNC milling machine or a machining center by whether you have a knife library, which is a gold standard.

Second, whether it is fully protected

In fact, this is not absolute for a lot of equipment, many CNC milling machines are gradually beginning to make a fully protected processing mode, of course, there are many old CNC milling machines using still open processing methods, or semi-protected processing methods, which to a certain extent and the current machining center still has a certain difference, Of course this distinction is not absolute (again).

In fact, this and the development process of equipment has a great relationship, in the primary stage of CNC processing equipment, in fact, many manufacturers do not pay much attention to the appearance of design and safety protection, basically stay in the function of the appeal, so many CNC milling machines have been made into an open form, or do a good point is semi-open form, Although this CNC milling machine in the function is not too big defects, but in the processing of safety and processing environment and other aspects of there are still great shortcomings, such as the processing of high temperature iron chips will splash on the human body, causing harm to the human body, the processing process used to cool the coolant tool will also splash the operator, dirty the operator's clothes and so on. Therefore, although the progress of research and development of production equipment, especially the invasion of foreign high-end equipment, the design and manufacturing of processing equipment in China is also taking strides towards a more humane, more beautiful, more environmentally friendly road.

This is a process, any progress needs a process, product technology, product environmental protection, is the future of the unified requirements for industrial products, but also the only way for the future development of industrial products.

Third, whether with automatic chip removal machine

This criterion is the same as the previous one, is not an absolute criterion, but also based on the process of processing equipment development to judge a mobile standard, the reason is also because of the previous equipment in the development of some knowledge of the function of the trade-off caused by many new CNC milling machines, full protection and automatic chip removal device are basically standard. And machining center is not much different.

But for those old CNC milling machines, this evaluation standard is still useful, after all, a equipment that does not even do a good job of protection, is in any case, do not dare to ask for what automatic chip removal, in fact, now the machinery industry practitioners, should thank this era, is this era to provide the liberation of our hands technology and ability, So that we can more easily and efficiently engage in our own work, and with the comprehensive development of industry 4.0, this liberation of the labor force is also accelerating, and even produce a lot of labor or labor methods of elimination, we must always be prepared.

4. Conclusion

Based on the above reasons, so if you want to choose a equipment, of course, it is better to choose a machining center, at least in the processing efficiency is much higher, the processing range is much larger, if combined with the five-axis head and rotary table, you can achieve more precise parts. For more machining center equipment consultation, please contact us

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.