BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

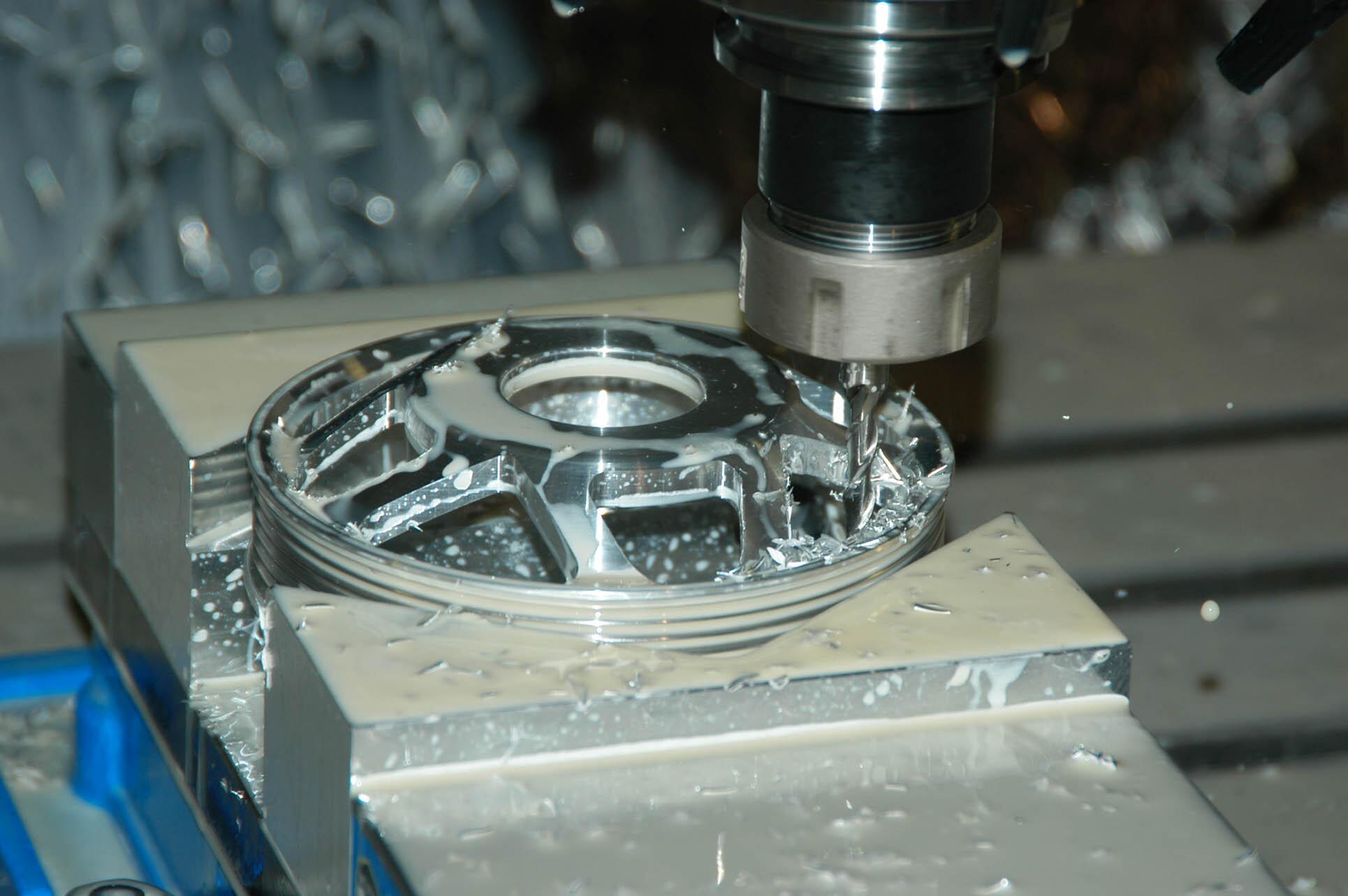

Over the past few years, CNC machining technology has evolved from simple machine tools to more complex machines. 5-axis CNC machining is one of the most advanced machining processes available today. It uses subtractive machining technology to provide unlimited possibilities for part creation. The technology uses cutting tools that work on five axes to cut the workpiece into the desired shape and size.

5-axis machining improves accuracy, efficiency and reliability. The increase in the number of axes also makes the 5-axis milling machine have better performance than similar machine tools. In addition, the process allows for full automation and management using computer numerical control (CNC). Therefore, many reliable CNC machine tool shops rely on this technology to provide accurate CNC machining services.

Advantages of 5-axis CNC machining

The ability to move tools and workpieces on up to 5 sides simultaneously provides several advantages for many industries. It enables cost-effective and efficient manufacturing of complex parts.

The following are the main advantages of this manufacturing process:

1. Simple setup operation

The 5-axis CNC machine can process 5 surfaces at the same time. For traditional 3-axis machining, you may need several Settings to handle parts with multiple faces. But 5-axis technology completes the machining of contour parts and other parts with multiple faces in a single structure. This allows you to manufacture parts with complex geometries with fewer setups.

2. Processing complex shapes (GD&T marks)

The extra rotation in this machining helps to achieve more complex designs and geometries. The machine enables seamless machining of circulars and angles, which was previously only possible with multiple special fixtures. The 5-axis milling process allows the part to be rotated in a single operation to achieve the desired geometry without the need for complex jigs.

In addition, the technology works perfectly with GD&T annotations to generate baseline features in a single operation. 5-axis milling is also suitable for CNC machining applications where surface profile tolerances are required on complex contour surfaces.

3. High precision and repeatability

Compared to CNC machining, the additional Settings involved in manual machining can cause mechanics to lose accurate alignment during manufacturing. However, the minimal setup involved in 5-axis CNC milling reduces the possibility of error and increases the accuracy required to achieve superior quality.

Today, different types of 5-axis machines eliminate the need to reposition the workpiece at different angles during machining. As a result, you can ensure that machining tolerances are improved. In addition, some machine configurations allow the use of shorter cutting tools. This increases tool life and ensures repeatability.

4. High cutting speed

5-axis machining ensures that the cutting tool is tangent to the cutting surface. This arrangement allows the tool to remove more material with each rotation. As a result, it reduces cycle time and overall processing costs.

5. Smooth surface finish

The additional shaft in this technology ensures the correct orientation of the workpiece, bringing it closer to the cutting tool. Therefore, you can use a shorter cutting tool to create the desired shape. These shorter tools can cut at very high speeds with little to no vibration.

Smaller vibrations further reduce the chance of "flutter" marks on the finished product. The vertical machining process also improves the utilization of the spindle when machining inclined surfaces. This way, you can use this technology to achieve a better surface finish and reduce the costs and time associated with post-processing.

6. Save cycle time and money

5-axis machined parts are usually completed in a single operation because of the high speed advantage of the process. The single setup involved helps save time and money. In addition, shorter tools with longer service life do not require constant tool replacement, saving money and time.

In addition, the 5-axis milling process can be automated, reducing manual operation and labor requirements. This reduces the labor costs involved in the process. Therefore, 5-axis CNC machining is a cost-effective solution to accelerate your product to market.

Disadvantages of 5-axis CNC machining

Although 5-axis CNC technology has many advantages, its use is not suitable for some applications.

Some disadvantages of this process include:

1. High initial cost

The cost of purchasing 5-axis CNC machines and their basic software is high. It is much higher than required for 3-axis machining centers. Similarly, the maintenance requirements of the machine are more challenging than traditional machine tools. This also directly increases the processing cost of the 5-axis workpiece.

2. Programming is difficult

These two additional rotational motions and their spatial trajectories are abstract and complex. For example, to work with free-form surfaces, you need to transform the coordinates several times; Perform complex space geometry operations; Consider the coordination of the axis movements.

All of this is necessary to avoid collisions and interference and ensure the correct amount of interpolation movement. Therefore, it is more difficult to program to obtain the required machining accuracy and surface quality.

3. Higher requirements for operators

5-axis CNC milling is an advanced technology that involves advanced programming, machine setup and operation. Therefore, the process requires highly skilled technical operators. This usually means an increase in labor costs.

4. Make full use of 5-axis CNC machining

Underutilization of 5-axis functionality is a common situation. Some operators do not understand the full capabilities of the machine. Others may not have the programming knowledge for cutting-edge operations.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.