BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

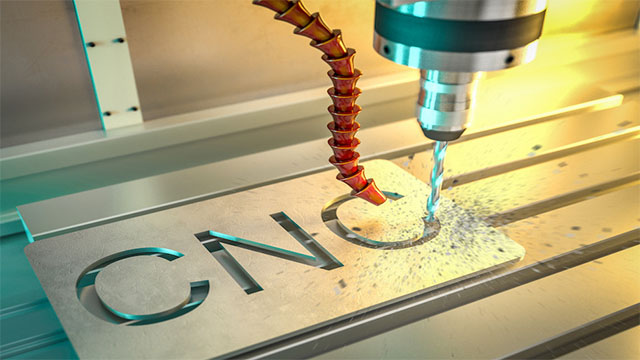

Sheet metal processing is a comprehensive cold processing process for sheet metal, reputable sheet metal processing plants are operated by CNC lathes. Some metal sheets are pressed through CNC machine tools to produce plastic deformation, forming a certain shape and size as required and further forming more complex parts through welding or a small amount of mechanical processing, such as chimneys commonly used in families, iron furnaces, and car shells are sheet metal parts. So what is the role of CNC machine tools in sheet metal processing?

1. Improve the accuracy of cutting

Sheet cutting is the first process in sheet metal processing, and the accuracy of cutting directly affects the processing quality of the following process. CNC shearing machine is composed of CNC device, servo system, measuring device and machine tool, which can accurately control the cutting scale of the plate. The numerical control shearing machine makes the mass of repeated blanking and eliminating the scribing and alignment processes, improving labor efficiency, and ensuring the size and diagonal accuracy of blanking.

2. Make the cutting process simpler

The CNC water jet cutting machine completes the processing of complex shapes and perforated sheet metal parts. The machine operator determines the sheet metal processing program according to the part drawing and process requirements. The operator can also directly write the program into the program memory through the machine tool operation panel. CNC water jet cutting machine makes complex shape structure processing simple, so that porous parts sheet metal processing once positioning cutting molding, improve the cutting process processing efficiency.

3. Visibility of molding data

Bending is a forming process in sheet metal processing. It is very important to select parameters such as mold width, bending radius, pressure value and pressure holding time reasonably. CNC bending machine automatically adjusts the sheet size according to the input parameters, calculates the bending pressure and contact time and other related parameters through the CNC system, all parameters are displayed on the screen, so that in the process of workpiece forming, you can do fine processing, there is evidence to rely on.

The application of CNC machine tools in production to improve sheet metal processing capacity can shape a good sheet metal processing manufacturer. Numerical control technology can solve the problems of high precision, complex shape and large batch in sheet metal processing. With the continuous development of numerical control technology, sheet metal processing calculation and processing equipment are also developing in the direction of linkage and composite processing.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.