BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

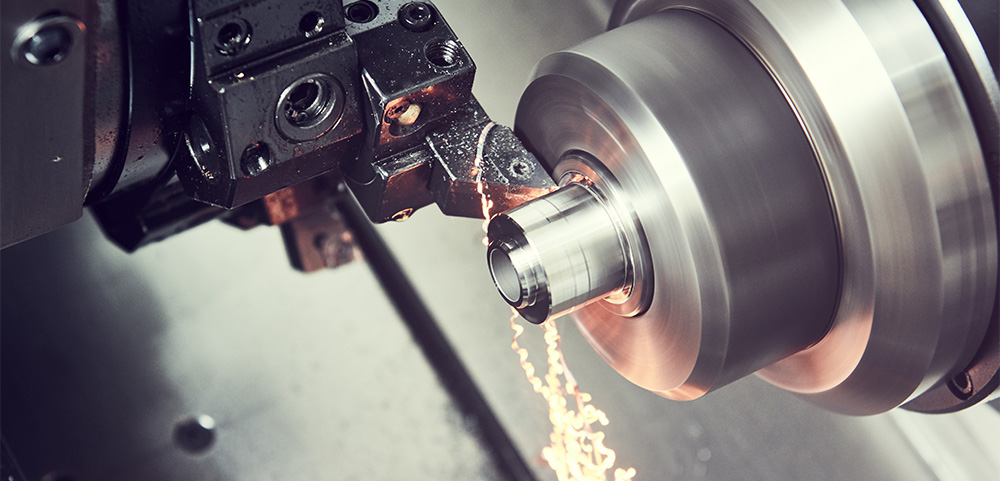

What is CNC Turning

CNC turning is the process of cutting materials to achieve a target shape and is classified as cutting. Lori as a CNC turning manufacturer will introduce the characteristics, processing sequence and soon of complex shape lathe processing by combining various tools and processing methods.

CNC turning process is a kind of cutting processing. Cutting also includes milling processing and opening processing, but in lathe processing, is the cutting tool contact rotating material, will not need to cut off the part while machining into the target shape.

CNC Turning is similar to CNC milling, which is also included in cutting, but is different in what is rotated. In CNC turning processing, is to make the processed material rotation, and in CNC milling processing, the material is fixed, is the rotary cuttingtool for processing.

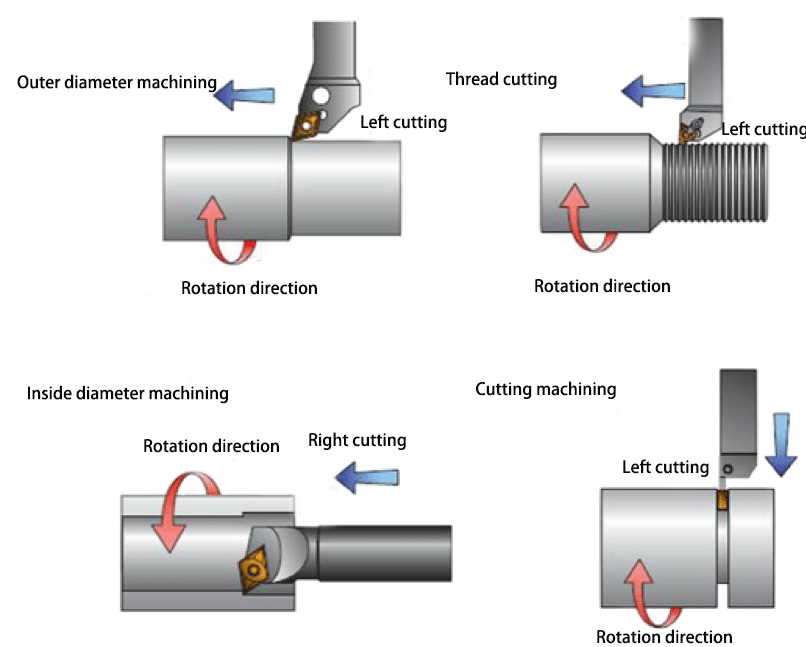

Basic machining methods of CNC turning

CNC lathe turning processing has outer diameter machining, inner diameter machining, thread cutting machining, cutting machining these four basic processing methods. The following describes the processing methods.

Outer diameter machining

Contour machining is the method of making the cutting tool contact from the outside of the rotating material. Is the most used machining method in CNC turning machining, used to beautify the surface of the finish and in the initial processing of the rough cutting for the target shape.

Outside diameter machining, the resulting chips may become entangled in the cutting tool. In the case of particularly high precision finishing, the Angle of the cutting tool needs to be adjusted in order to prevent chip entanglement and poor accuracy.

Inside diameter machining

In the inner diameter machining, the inside of a material is cut, thereby enlarging the holes in the material created by opening machining. Used to adjust the size of the hole and beautify the inner surface.

For inside diameter machining, the tool needs to be lengthened according to the depth of the hole to be machined. However, long cutting tools are prone to deviation, so we must pay attention to the accuracy reduction. In addition, since chips accumulate in the hole, they need to be removed frequently.

Thread cutting

Thread cutting is a machining method that generates pitch. In CNC lathe turning, both external and internal threads can be processed with special thread cutting tools. In the case of milling and machining centers, it is usually only possible to make internal threads, so the ability to make external threads as well is one of the great advantages of CNC lathe processing.

Contact the special tool for thread cutting with the material, so that the tool moves at a constant speed. In order to equalize pitch, an "automatic feed function" is often used to maintain constant speed.

Opening machining

Opening machining is the method by which a drill is pressed against a rotating material to open a hole. When machining the inner diameter, it is necessary to punch holes in advance, so that special cutting tools can enter, at this time, the use of opening processing. The precision of drilling with drill is not too high, so it is generally used to finish after opening holes of the required size.

Cutting machining

Cutting is the process by which a cutter is pressed against a material to cut off unwanted parts. It's like cutting a cylinder into a circular slice.

You need to use tools with thin blades, and you need to check for vibrations and sounds while working, so you need some skill. In order to carry out high precision CNC Turning machining, some measures need to be taken, such as the use of flexible blades, the use of oil when cutting, etc.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.