BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

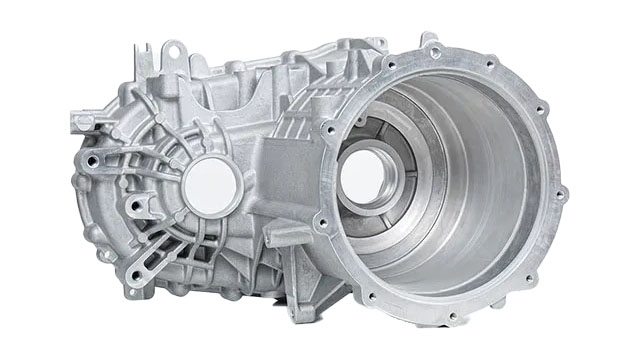

Aluminum die casting is a kind of renewable material with light weight, high toughness, high strength and excellent vibration damping performance. It is widely used in aerospace engineering, vehicles, electronic equipment, diagnosis and treatment and other fields. For the surface treatment of magnesium alloy die casting, spray surface treatment can be used.

Spraying is the entire process of spraying paint splashed on the surface of aluminum die casting. Surface treatment includes removal of surface residues, polishing, passivation treatment to improve the surface quality and corrosion resistance of aluminum die casting. Surface treatment can also be carried out at different stages of magnesium alloy die casting, from stamping die, smelting, casting, laser cutting, production and processing, painting, etc., to ensure the overall quality of aluminum die casting.

Depending on the sizes and appearances of aluminum die castings, as well as the characteristics and types of spray coatings, magnesium alloy die castings can also be sprayed with surface treatment. Sprayed surface treatment can also improve the appearance of the product and corrosion resistance to ensure that magnesium alloy die casting is allowed. Mainly due to the unique chemical and physical properties of aluminum die casting, it will affect the surface treatment method of sprayed architectural coatings. The high reflectance of aluminum die casting requires special primers and architectural coatings to obtain the actual effect of good surface treatment.

Before spraying the surface treatment, the magnesium alloy die casting must be passivated with stainless steel to ensure that the coating can fully adhere to the surface layer. The main reason is that the high reaction of aluminum die casting will make the coating cannot quickly adhere to the surface layer. In the passivation process of stainless steel, suitable aluminum die casting raw materials should be selected to obtain better surface quality and coating adhesion.

Magnesium alloy die casting can be sprayed surface treatment. The surface treatment can also improve the appearance and corrosion resistance of the product to ensure that magnesium alloy die-casting parts are allowed. Before spraying the surface treatment, the magnesium alloy die-cast parts must be passivated with stainless steel to ensure that the coating can fully adhere to the surface. Therefore, when spraying the surface treatment, attention should be paid to the choice of coating, stainless steel passivation process and the adhesion of the coating.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.