BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

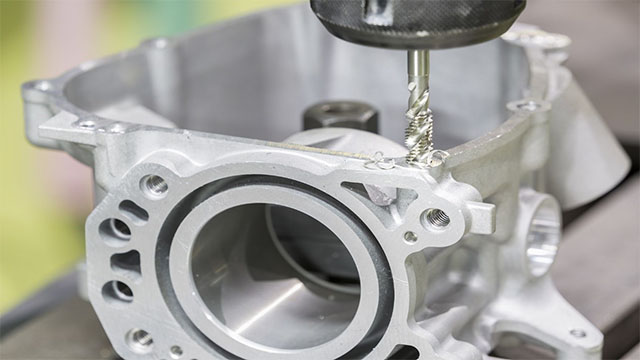

Zinc alloy die casting parts are currently widely used in all kinds of decorative surfaces, such as: belt buckle, tie clip, toys, architectural decoration, furniture accessories, all kinds of metal buckles, usually casting surface quality requirements are very high. However, in the production process, defects will inevitably occur. The following is the common defects causes and solutions of zinc alloy die casting parts.

1. Zinc alloy die casting parts have local deformation or surface cracks.

Reason: Casting wall is too thin, it shrinks and deforms; the number of ejector rods is not enough or the distribution is uneven, resulting in uneven force; the fixed plate of the pusher rod is skewed when working, resulting in a small force on one side and a large force on the other side, which causes cracks and deformations of the product. The solution is Adjust and reinstall the push rod fixed plate, increase the number of ejector rod, adjust its distribution position and make the casting ejector force balance.

2. Some parts of zinc alloy die casting are not formed, and the cavity is not full.

Reason: Air can not be discharged; the pressure of the press machine is too small, the metal liquid temperature is low, the die casting mold temperature is too low, the metal liquid is insufficient, and the injection speed is too high. Zinc alloy die casting factory tells you that the method that can be taken: Replace the large pressure die casting machine, increase die casting mold and liquid metal temperature, add enough metal liquid, reduce the injection speed and increase the thickness of the feed port.

3. Zinc alloy die casting outer contour is not clear, can not form, local lack of material.

Reason: The thickness of the feed port is too large; the pressure of die casting machine is not enough, the injection pressure is too low; the gate was mispositioned and the metal had a frontal impact. The solution is change the gate position to prevent the positive impact on the casting, replace the die-casting machine with a larger die-casting ratio and reduce the inlet channel thickness.

The above introduces the common defects causes and solutions of zinc alloy die casting parts, we have a certain understanding, when there are some defects in zinc alloy die casting parts, we can refer to the above content to solve.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.