BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

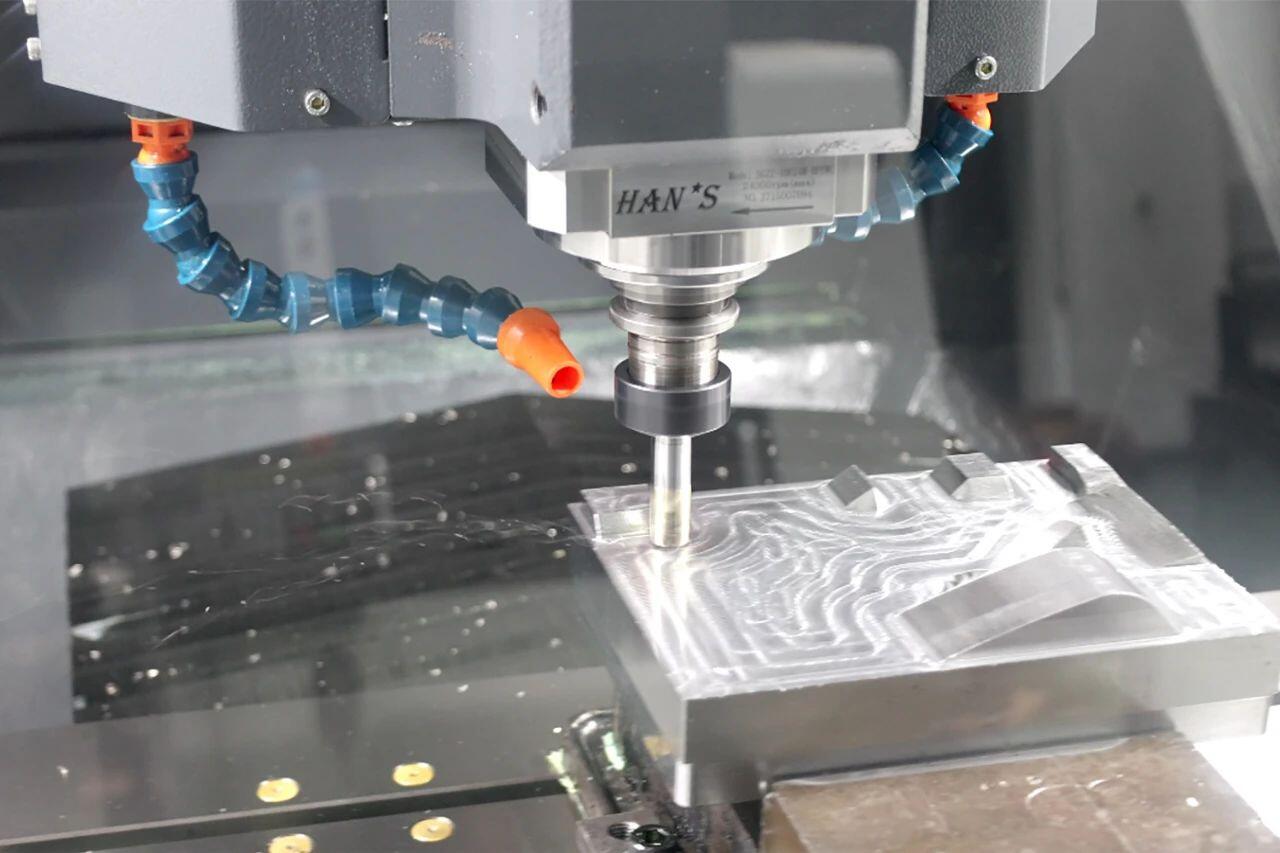

A machining center is a type of CNC machine tool capable of performing various part processing tasks, with its performance and precision levels crucial for machining efficiency and quality. According to the GB/T 17424.1-2015 standard, machining centers can be classified into the following five grades:

1. General Machining Center: Suitable for applications where moderate part processing precision is required, with maximum positioning accuracy ranging from 0.015 to 0.02mm.

2. Medium to High-End Machining Center: Suitable for high-precision machining requirements, with maximum positioning accuracy ranging from 0.008 to 0.012mm.

3. High-Speed Machining Center: Suitable for high-speed cutting applications, with maximum spindle speeds exceeding 20,000 rpm.

4. Ultra-Precision Machining Center: Suitable for ultra-high precision machining requirements, with maximum positioning accuracy ranging from 0.002 to 0.004mm.

5. Multi-Axis Machining Center: Suitable for applications requiring multi-axis machining capabilities, capable of achieving five or more axes of movement.

Different grades of machining centers are suitable for various machining requirements and fields.

General machining centers are used in mechanical processing, electronic precision machining, mold making, and automotive parts manufacturing.

Medium to high-end machining centers find applications in aerospace, defense, shipbuilding, petroleum, and chemical industries requiring high precision.

High-speed machining centers are used in high-speed cutting applications, while ultra-precision machining centers are employed in fields such as optics, medical devices, and microelectronics for ultra-precision requirements.

Multi-axis machining centers are utilized for complex surface machining and assembly of intricate parts.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.