BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

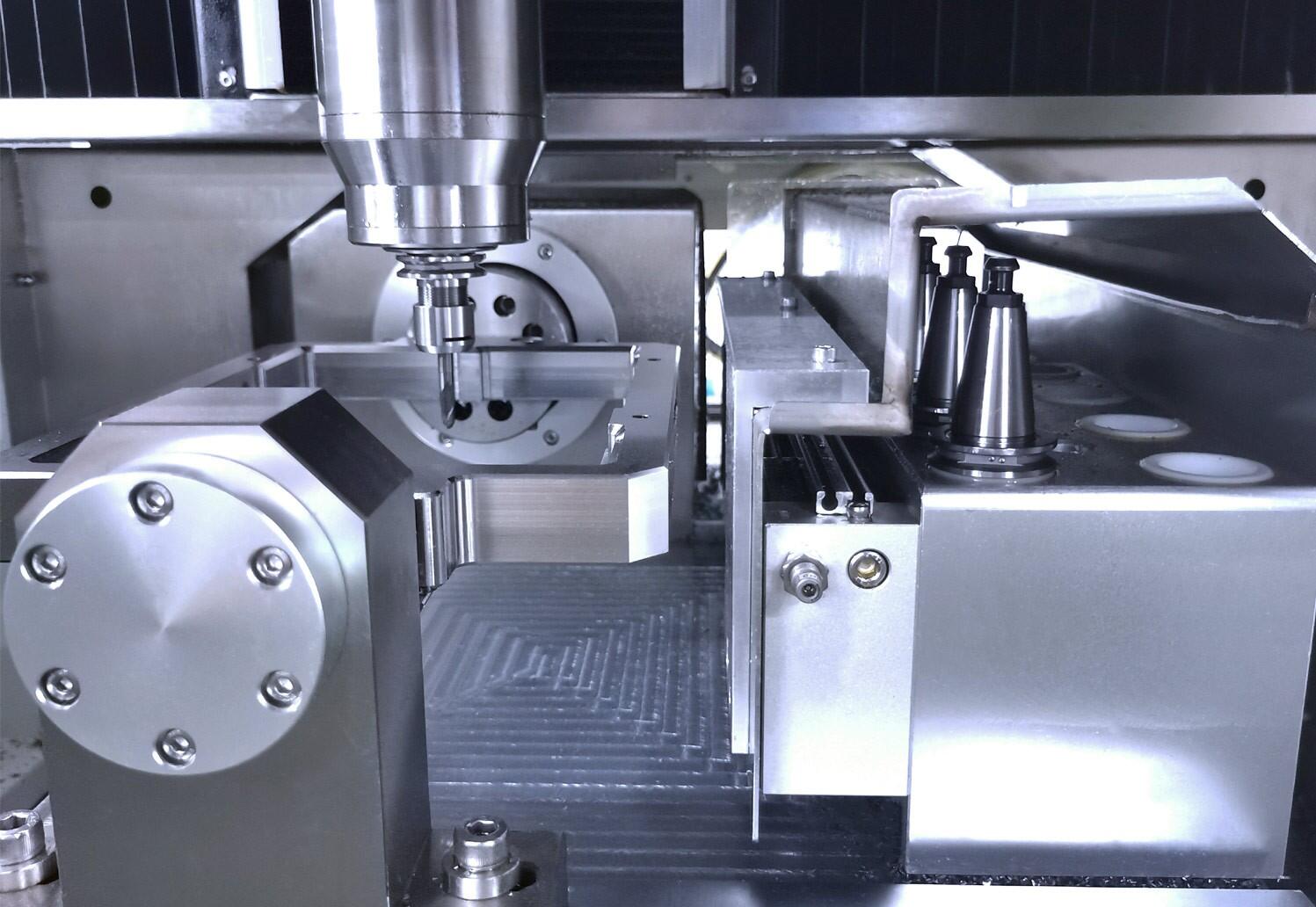

In modern manufacturing, engraving milling machines and machining centers are two common types of CNC machine tools that differ in structure, function, and application. Here are the differences between engraving milling machines and machining centers:

1. Structure and Function

Machining Center: A machining center is a versatile CNC machine tool typically equipped with three or more axes of movement, such as X, Y, Z axes. In addition to basic milling functions, machining centers can perform drilling, boring, tapping, and other processes. They usually have a larger worktable area and higher cutting speeds, suitable for efficient and precise machining of metal parts.

Engraving Milling Machine: Engraving milling machines focus primarily on flat engraving and surface finishing, usually structured with two or three axes, such as X, Y axes. They operate at relatively lower cutting speeds and are mainly used for processing non-metallic materials such as wood, plastic, acrylic, and foam. Engraving milling machines are typically equipped with high-speed spindles and various types of tools for intricate carving and surface decoration.

2. Application Areas

Machining Center: Due to its high speed and precision, machining centers are widely used in aerospace, automotive manufacturing, mold making, and mechanical processing industries. They are particularly suitable for precision machining of complex parts and large-scale production.

Engraving Milling Machine: Engraving milling machines are primarily used in fields such as art, signage, advertising, furniture, etc., for decoration and 2D/3D carving. They are suitable for personalized customization, small batch production, and sample making.

3. Performance Metrics

Spindle Speed: Machining centers generally have lower spindle speeds compared to engraving milling machines, especially high-speed engraving milling machines that can achieve higher speeds.

Spindle Power: The spindle power of machining centers is usually greater than that of engraving milling machines, suitable for heavy cutting and roughing operations.

Cutting Volume: Machining centers can handle larger cutting volumes, suitable for heavy cutting and roughing; engraving milling machines handle smaller cutting volumes, suitable for finishing operations.

Speed: Engraving milling machines typically have faster movement and feed speeds compared to machining centers, especially high-speed machines equipped with linear motors that can achieve speeds up to 120 m/min.

Accuracy: While all three types offer similar precision, machining centers generally have stricter accuracy requirements.

The choice between an engraving milling machine and a machining center depends on specific manufacturing needs. For large-scale, high-efficiency metal parts machining, a machining center is the preferred choice. For intricate carving and surface decoration, especially on non-metallic materials, an engraving milling machine is more suitable.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.