BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

In recent years, 3D printing technology based on the principle of melt deposition molding has achieved considerable development, and has achieved industrial application in many fields such as aerospace, automotive, medical treatment, and has become an important part of advanced manufacturing.

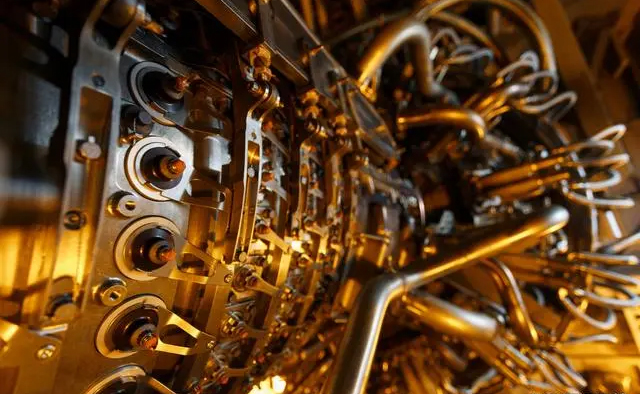

The aerospace industry is one of the first areas where FDM 3D printing technology has landed. Using 3D printing technology, lightweight aerospace parts can be printed, which not only reduces manufacturing and transportation costs, but also realizes the efficient production of parts. For example, spacex's Falcon 9 rocket uses 3D printing technology to create many key power components such as turbomuders. It is expected that the commercial space industry will significantly increase the proportion of 3D printing technology in the future.

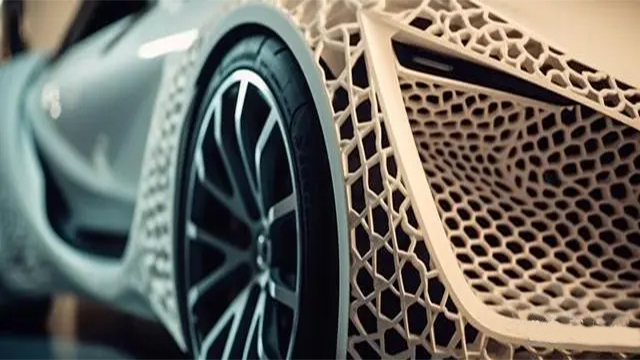

The automotive industry is also an important application area for 3D printing technology. On flagship models such as the S Series, German Mercedes-Benz extensively uses 3D printing to produce automotive functional parts such as air conditioning vents and interior trim parts, which not only improves production efficiency, but also enables highly customized parts. In addition, the use of 3D printing technology can also shorten the development cycle of new cars and reduce design risks. According to statistics, by 2025, the demand for 3D printing in the automotive industry will achieve double-digit growth.

In the medical field, the application of FDM 3D printing is also becoming more and more extensive. It enables custom printing of dental braces, artificial bones and other implants, enabling precision medicine and significantly improving surgical success. In addition, the use of 3D printing technology can also make customized drug delivery devices to achieve accurate drug delivery to patients. It can be predicted that 3D printing technology has broad application prospects in the entire medical field.

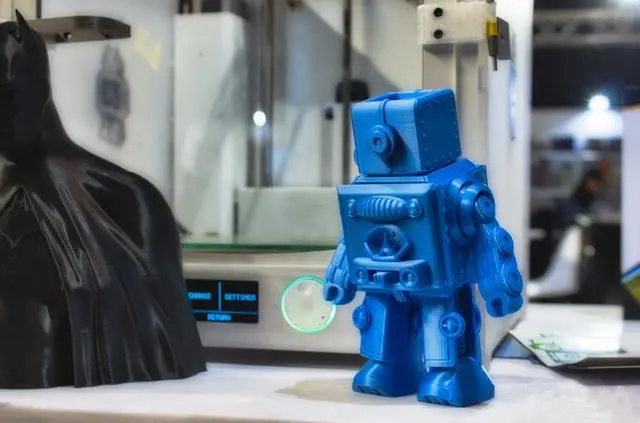

At present, FDM 3D printing technology is also widely used in industrial design, art design, teaching demonstration and other fields. It can quickly generate the concept prototype of the product, accelerate the design iteration, and greatly shorten the time to market. In the context of the growing demand for personalization, this advantage will also receive more attention.

In summary, FDM 3D printing technology is promoting industrial change, and its applications in aerospace, automotive, medical and other fields are becoming more and more mature and extensive. It can be expected that in the future, 3D printing as an efficient customized production method, its application range will continue to expand, and it will have an important impact and promote the upgrading of related industries.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.