BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

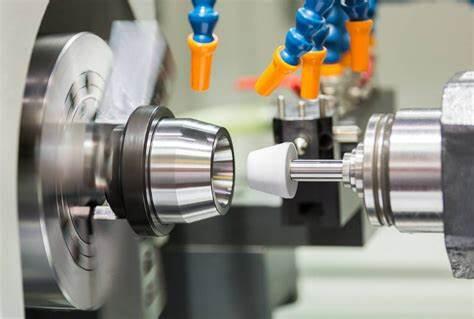

Grinding machining is a kind of finishing machining which is widely used. After processing, the precision can reach IT5 level, and the surface roughness can reach Ra0.1~0.006μm. Both metal and non-metal materials can be processed.

When grinding, there is a dispersed fine-grained sand (abrasive and abrasive) between the lapping tool and the surface of the workpiece to exert a certain pressure between the two, and make it produce complex relative motion, so that after the grinding of the sand and the chemical and physical action of the abrasive agent, an extremely thin layer is removed on the surface of the workpiece, and high accuracy and small surface roughness are obtained.

The grinding method is divided into the following three categories according to the conditions of use of the grinding agent:

1. Dry Grinding Only

A small amount of lubricant additive is applied to the surface of the lapping tool. In the grinding process, the sand is basically fixed on the lapping tool, and its grinding function is mainly sliding grinding. This method has low productivity, but can achieve high machining accuracy and small surface roughness value (Ra0.02 ~ 0.01μm).

2. Wet Grinding

In the grinding process, the grinding agent is applied to the lapping tool and the grinding is carried out with dispersed sand particles. In addition to sand, there are kerosene, oil, oleic acid, stearic acid and other substances in the abrasive. In the grinding process, part of the sand exists between the lapping tool and the workpiece. At this time, the sand is mainly rolled grinding, with high productivity and surface roughness Ra0.04 ~ 0.02μm, which is generally used for roughing, but the processing surface is generally dull.

![]()

3. Soft Abrasive Grinding

In the grinding process, the abrasive agent with chromium oxide as an abrasive is coated on the working surface of the lashing tool, because the abrasive is softer than the lashing tool and the workpiece, so the abrasive is suspended between the workpiece and the lashing tool during the grinding process, mainly using the chemical action between the abrasive agent and the workpiece surface, resulting in a very soft oxide film, and the film at the convex point is easily ground by the abrasive. This method can obtain very fine surface roughness (Ra0.02 ~ 0.01μm).

SLS process in the application of automotive structure optimization, automotive companies through 3D printing technology to achieve the complexity of the filling structure, reduce the weight of the body while improving the strength of the parts, and can absorb the energy of the impact process.

![]()

The application field of grinding processing technology is very wide, covering almost all manufacturing industries that require high precision and high quality surface treatment. At the same time, with the continuous development and improvement of grinding processing technology, it will have a broader application prospect in the future.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.