BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

Electroplating technology began to rise in the 20th century and is widely used in the fields of material protection and decoration. In the 21st century, science and technology have advanced by leaps and bounds, with mutual penetration and rapid development of interdisciplinary disciplines. Electroplating technology has also achieved its own breakthroughs in this wave of scientific and technological development, gradually developing from protective decorative electroplating to functional electroplating, and its application fields have been expanded to microelectronics, micro-motor systems (MEMS) and remanufacturing and other high-tech fields, and developed into a key technology in such high-tech fields. The relevant research progress is introduced here.

1.Ni-Co Alloy Coating

Ni-Co alloy coating has excellent high temperature wear resistance, and has been successfully applied to the mold surface of the key component of the continuous casting mill in steel mills, greatly increasing the service life of the mold. The continuous casting mould works at about 350℃. Continuous casting mold should have good thermal conductivity, but also need to withstand the friction between the billet. For this reason, the whole body of the continuous casting mold is made of copper alloy, and a high temperature and wear-resistant material layer with a thickness of several millimeters is prepared on the surface of the mold in contact with the billet.

The excellent high temperature wear resistance of Ni-Co alloy coating is suitable for the high temperature wear resistance of the surface in contact with the billet. At present, Ni-Co alloy coating has been widely used in the surface coating material of continuous casting mold

2.Electroplating Nanometer Metal Multilayer Film

Nanometer metal multilayer film is a kind of metal multilayer film formed by alternating superposition of different metal layers with thickness in nanometer scale. Because the thickness of the metal layers of the nano-metal multilayer films is in the nanometer scale, these thin films often exhibit unique mechanical properties, electromagnetic properties and optical properties of nano-materials. When the multilayer structure [NiFe(16 nm) /Cu(26nm)] is 80 layers, the GMR value can reach 64%.

3. Composite Plating Technology

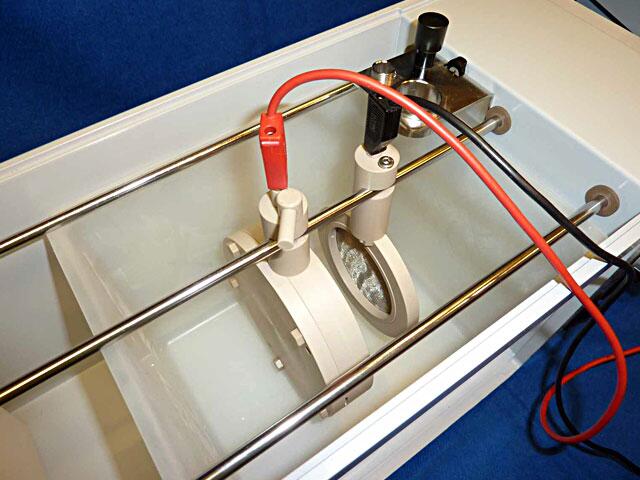

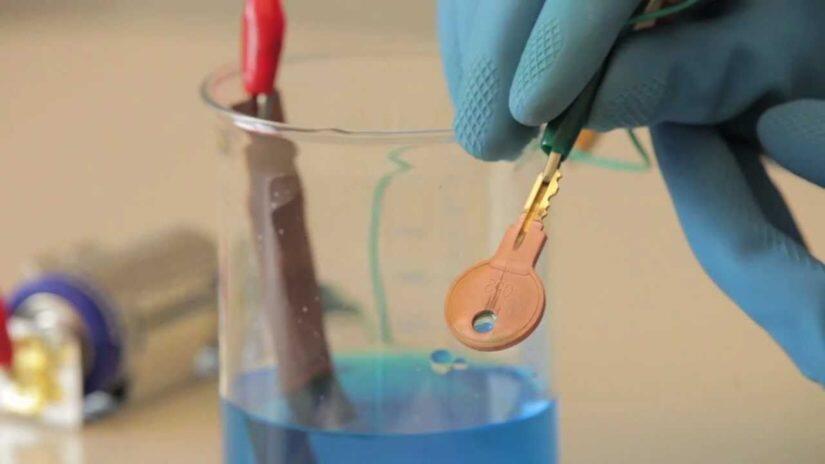

Composite plating technology by adding inorganic material and polymer material powder into the plating solution, stirring to make it uniformly dispersed in the plating solution, along with the plating or electroless plating process to embed such powder into the coating, forming composite coating material.

In general, electroplating technology has a wide range of applications, and with the continuous progress of technology, it will have broader application prospects in the future. At the same time, we also need to pay attention to the environmental pollution caused by the electroplating process, and actively take measures to prevent and control it in order to achieve the sustainable development of electroplating technology.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.