BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

1. The speeds of the wires

The fast wire speed is greater than or equal to 2.5m/s, the common value is 6 to 10m/s, and the slow wire cutting wire speed is less than or equal to 2.5m/s, the common values 0.25 to 0.001m/s.

2. The working states of the electrode wires

Fast wire cutting machine is reciprocating wire supply, and it is reusable. The slow wire cutting machine is one-way moving, and it is disposable.

3. The materials of electrode wires

The materials of electrode wire of the fast wire cutting machine tool are molybdenum wire and tungsten molybdenum alloy. The slow wire cutting is the electrode wire using brass, copper, copper as the main alloy or plated composite material.

4. The diameters of the electrode wires

The diameter of the electrode wire of the fast wire cutting machine is 0.03 to 0.25mm, and the common value is 0.12 to 0.2mm, while the diameter of the slow wire cutting electrode wire is 0.003 to 0.3mm, and the common value is 0.2mm.

5. Threading methods

The threading method of fast wire cutting can only be manual, while the threading method of slow wire cutting can be manual or automatic.

6. Working electrode wire lengths

The working electrode length of fast wire cutting is hundreds of meters, while the working electrode length of slow wire cutting is several kilometers.

7. The vibrations of the electrode wires

The vibration of the fast wire cutting electrode wire is larger, while the vibration of the slow wire cutting electrode wire is smaller.

8. The tensions of the electrode wires

The tension of the fast wire cutting electrode is fixed after the wire, and the tension of the slow wire cutting electrode is adjustable after the wire, usually 2.0 to 25.

9. Silk system structures

The structure of the moving wire system of the fast wire cutting machine is simple, while that of the moving wire system of the slow wire cutting machine is complex.

10. Pulse power supplies

The open circuit voltage of the fast wire cutting machine is 80~100V and the working current is 1~5A, while the open circuit voltage of the slow wire cutting machine is 300V and the working current is 1~32A.

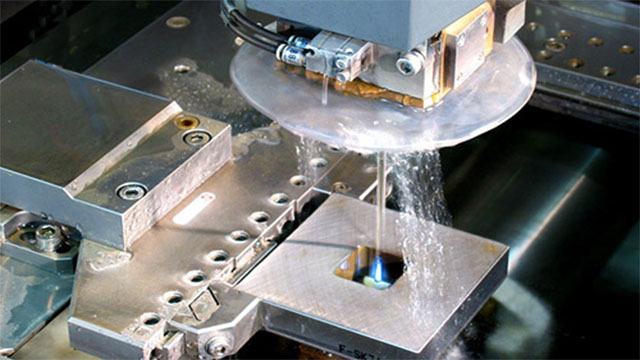

11. Working fluid

The working fluid of the fast wire cutting machine are milk substitute or water based working fluid, while the slow wire cutting machine are deionized water, and kerosene is used in some cases.

12. The resistivities of working fluid

The resistivity of working fluid of the fast wire cutting machine is 0.5~50, and the resistivity of working fluid of the slow wire cutting machine is 10~100.

13. Types of wire guide mechanisms

The type of wire guide mechanism of fast walking wire cutting machine tool is the use of guide wheel, and its life is short, while the type of working fluid wire guide mechanism of slow walking wire cutting machine tool is the use of guide, and its life is long.

14. The prices

Fast wire cutting is cheap, slow wire cutting is expensive.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.