BETTER TOUCH BETTER BUSINESS

Contact Sales at Lori.

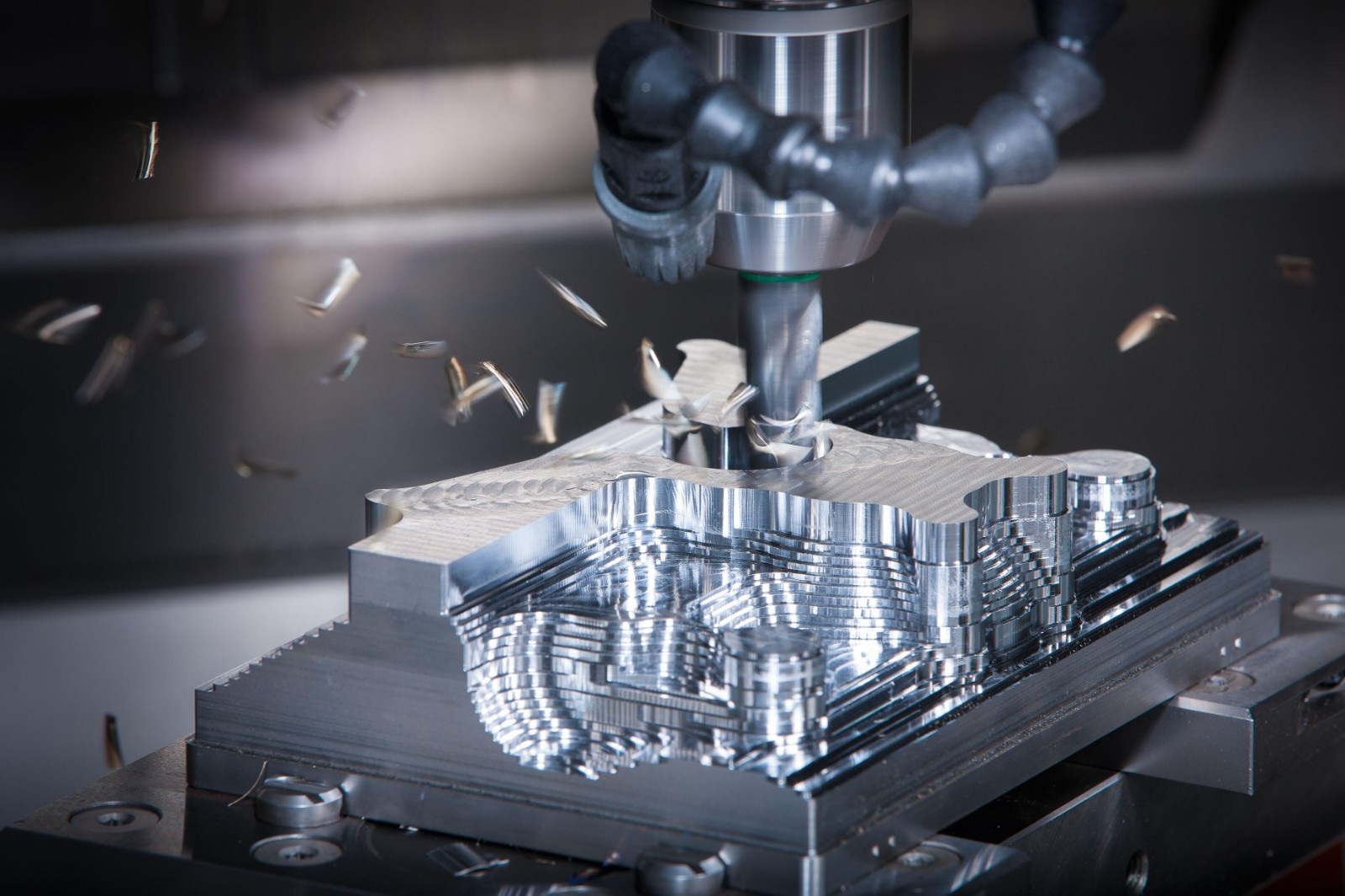

1.Dimensional accuracy: The dimensional accuracy of large parts in the processing of large parts is extremely high, and it is necessary to ensure that each processing link can accurately control the size to avoid the accumulation of errors. This usually requires the use of high-precision measuring equipment and processing tools, as well as reasonable processing technology.

2.Surface quality: the surface quality of parts directly affects its performance and service life. In the processing process, it is necessary to ensure the surface finish of the parts, no burrs, no cracks and other defects, and it may be necessary to carry out surface quenching, sandblasting, shot blasting and other treatments to improve the surface hardness and wear resistance.

3.Material properties: the material properties of large parts are crucial to their performance. In the selection of materials, it is necessary to consider its strength, toughness, durability, corrosion resistance and other factors, while minimizing material loss.

4.Heat treatment: heat treatment is an important means to improve material properties, through a reasonable heat treatment process, can improve the hardness of parts, wear resistance, fatigue strength and other properties.

5.Processing stability: During the processing of large parts, it is necessary to ensure the stability of machine tools, tools, fixtures and other equipment to avoid processing errors caused by vibration or loosening of equipment.

6.Process optimization: by optimizing the processing technology, such as the use of reasonable cutting parameters, tool selection, processing sequence, etc., can improve processing efficiency and reduce production costs.

Copyright © 2025 Shenzhen Lori Technology Co.Ltd. | All Rights Reserved.